- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

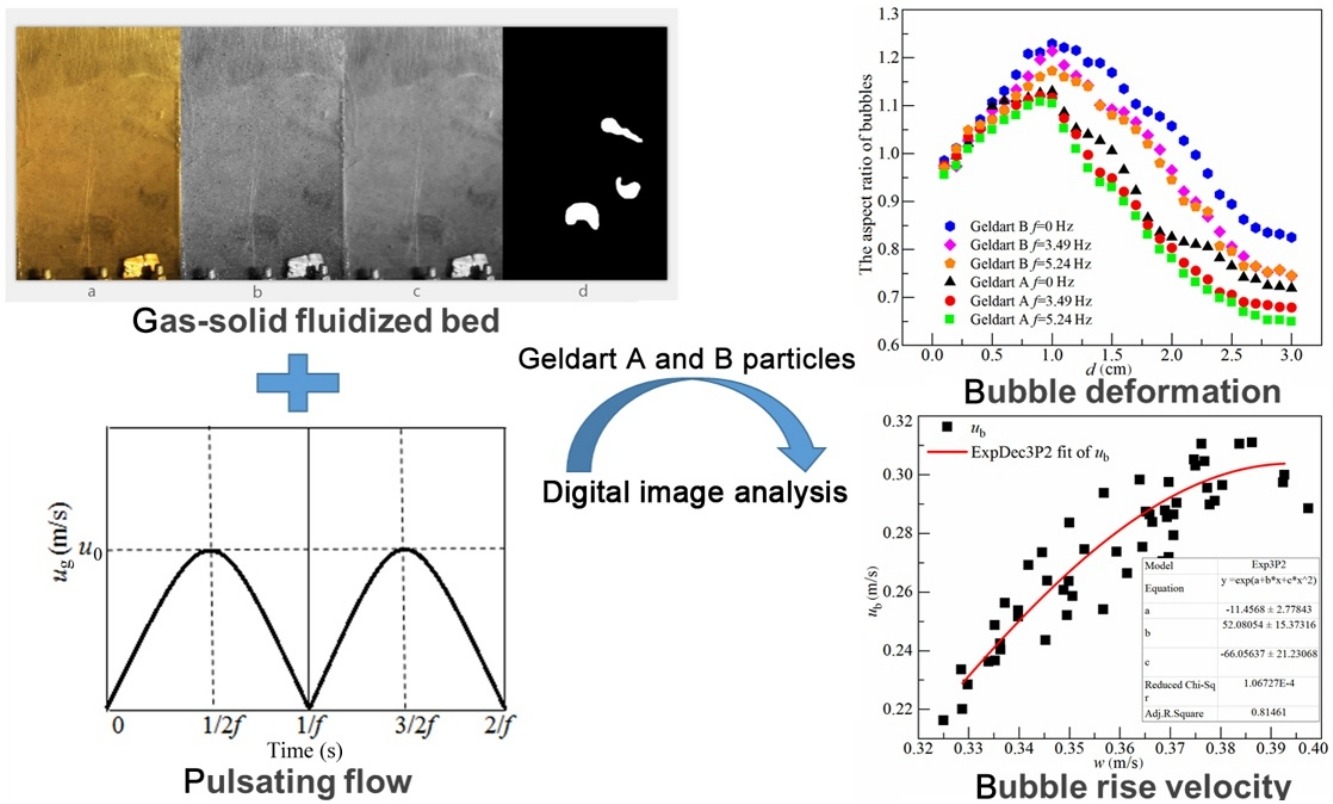

• The bubble motions produced by two different particles in a bed were studied.

• The deformations of bubbles under different operating conditions were examined.

• A model to predict the velocity of bubbles in pulsed gas–solid fluidized bed is proposed.

Pulsed gas–solid fluidized beds can effectively separate fine coal, and bubbles play an important role in creating suitable separation conditions. The present study performed statistical and image analyses of the evolution of bubbles in a two-dimensional pulsed gas–solid fluidized bed using a high-speed dynamic camera. The effects of apparent gas velocity, pulsation frequency and particle size on bubble characteristics and bed expansion were analyzed. The results indicate that, when a fluctuation frequency is added, the expansion height of the bed increases, the effect of attachment to the bed wall decreases, the leading diameter and rising velocity of the bubbles both decrease and the degree of bubble deformation increases. These trends are also more obvious for fine particles. These findings demonstrate that a high density pulsed gas–solid fluidized bed can effectively combine gases and solids to produce a uniform, stable mixture. The bubble diameter and rising velocity were also simulated in the present work, and the relationship between the two was established using a fitting model with an error within 5%. This model provides an effective means of predicting bubble velocity as well as studying the distribution of the bubble phase and improving the stability of the bed density.