- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

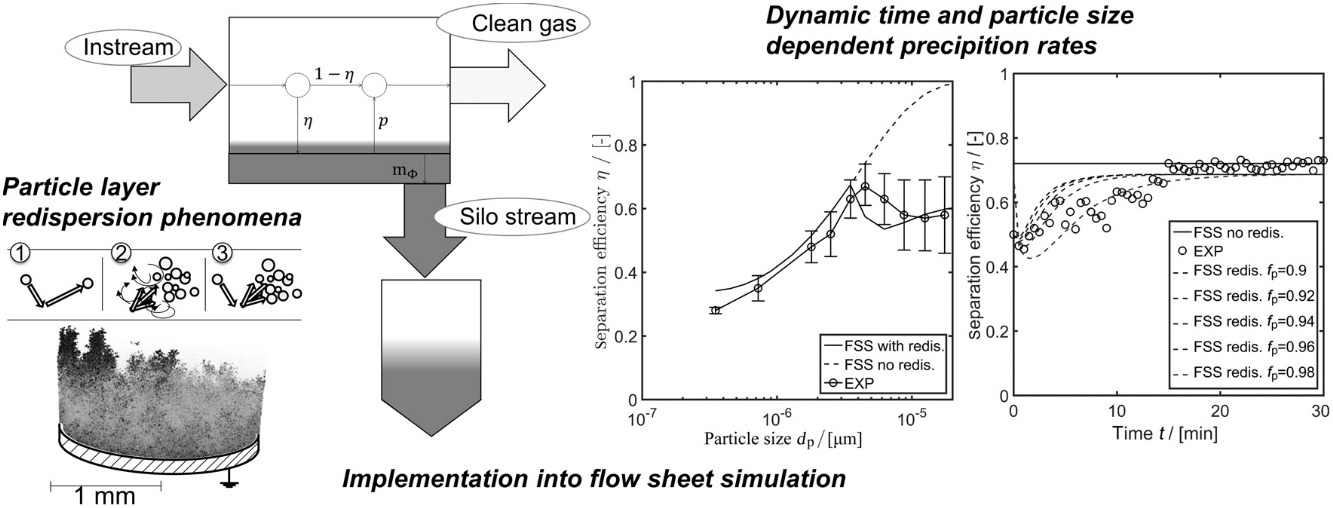

• Macroscopic simulation of an electrostatic precipitator.

• Particle charging and transport have density and permittivity effects.

• These effects affect the precipitation of submicron- and micron-sized particles.

• The effect of redispersion effects on separation efficiency is discussed.

Electrostatic precipitators clean away the particulate matter of exhaust gases in manifold industrial processes. Parameter studies of particle separation in the size range of several 100 nm to 25 μm is of particular interest for the prediction of precipitation efficiencies and emissions. Models typically cover the transport of particles towards walls of the precipitator. However, no model yet covers the possible re-entrainment of particles from layers formed at the walls back into the gas flow. This study presents the implementation of a new time-resolving model for electrostatic precipitation utilizing a re-entrainment model. Experimental data support the results of modelling. The model uses a statistical approach based on properties of the particulate layer forming at the precipitator walls. The model is used for the analysis of the redispersion of particles in a laboratory-scale electrostatic precipitator (Sander, Gawor, & Fritsching, 2018). Results show reduced precipitation efficiencies for particles larger than 5 μm as particles have higher kinetic impact energies and lower bounding energy at the layer surface. Time dynamics reveal a steady-state behavior of the separation for CaCO3 (limestone, trademark "Ulmer Weiss®") while Al2O3 (trademark "Pural NF®") precipitation is affected by layer buildup at the walls increasing over several minutes.