- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

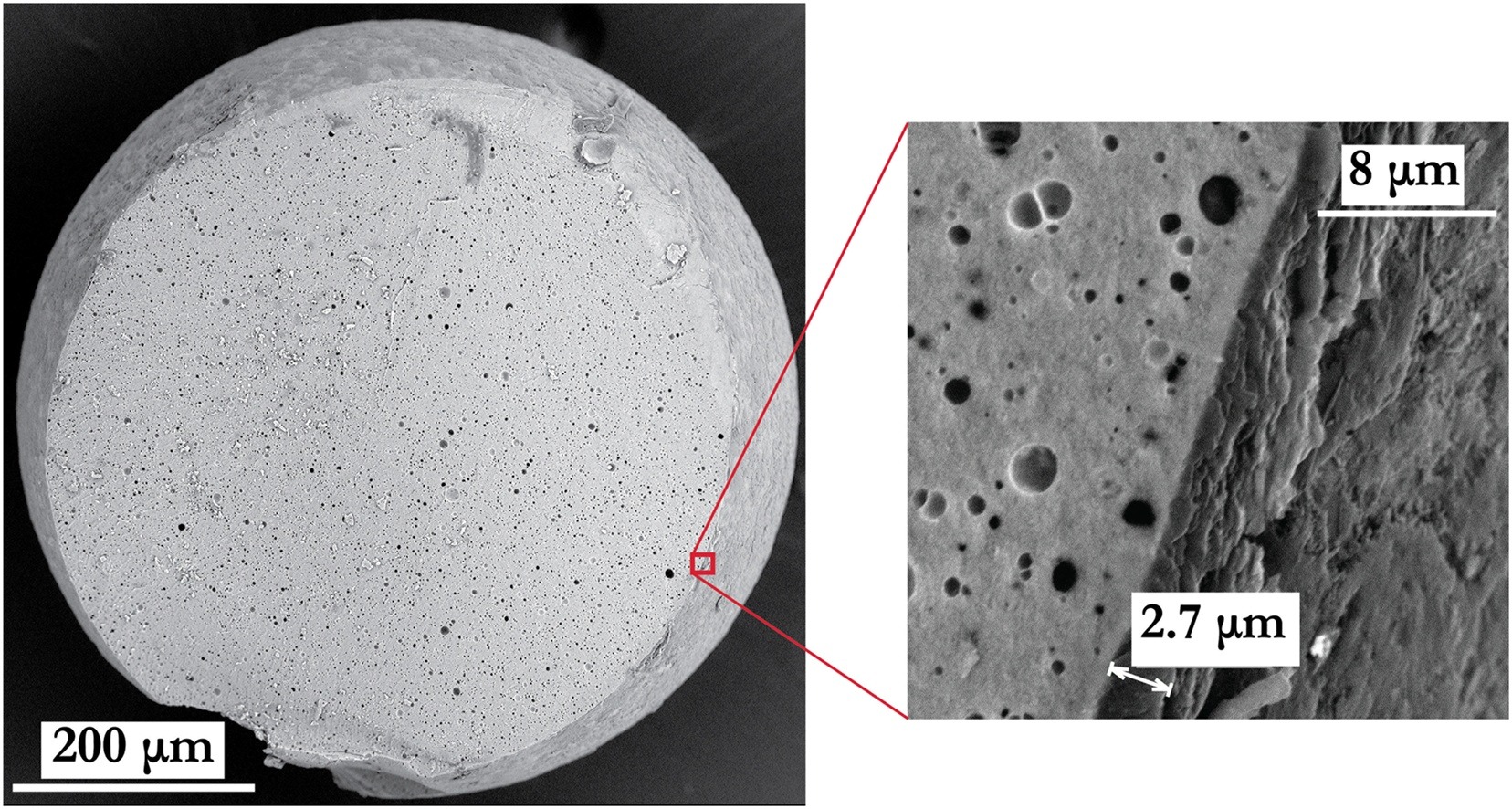

• Presentation of ultrathin particle coating in a proof-of-principle experiment.

• Particles were coated in a lab-scale fluidized bed with a novel aerosol generator.

• The process is shown to be feasible with an improvable yield in the range of 30%.

• Monte Carlo simulations indicate reduced processing times and material need.

• Application may be scalable and affordable production of high-resolution coatings.

In this work, we demonstrate that particles can be coated in a fluidized bed with coating solution provided by a novel aerosol generator. Aerosol droplets are smaller than 1 μm in volume-based diameter, hence they are very much smaller than droplets in conventional spray fluidized bed processes (around 40 μm). A proof-of-principle experiment with 30% aqueous coating solution of sodium benzoate and γ-Al2O3 core particles in 150 mm fluidized bed fed with droplet aerosol supplied from the chamber side is presented. To simultaneously coat and dry the particles, inlet of fluidization air was at 50 °C. Moreover, Monte Carlo simulations of coating with small aerosol and large spray droplets were conducted. Due to dramatically smaller building blocks, ultrathin particle coating of high-resolution (very small layer thickness) can be attained with the new aerosol process, with the potential of even going nanoscale. Full coverage of particles is reached substantially faster than in the conventional process, so that material demand is much lower and sensitive materials can be processed in short residence time. Solids yield of around 30% was much higher than expected, that is considered to be technically viable and may be enhanced by the recycling of entrained solids or better equipment design.