- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

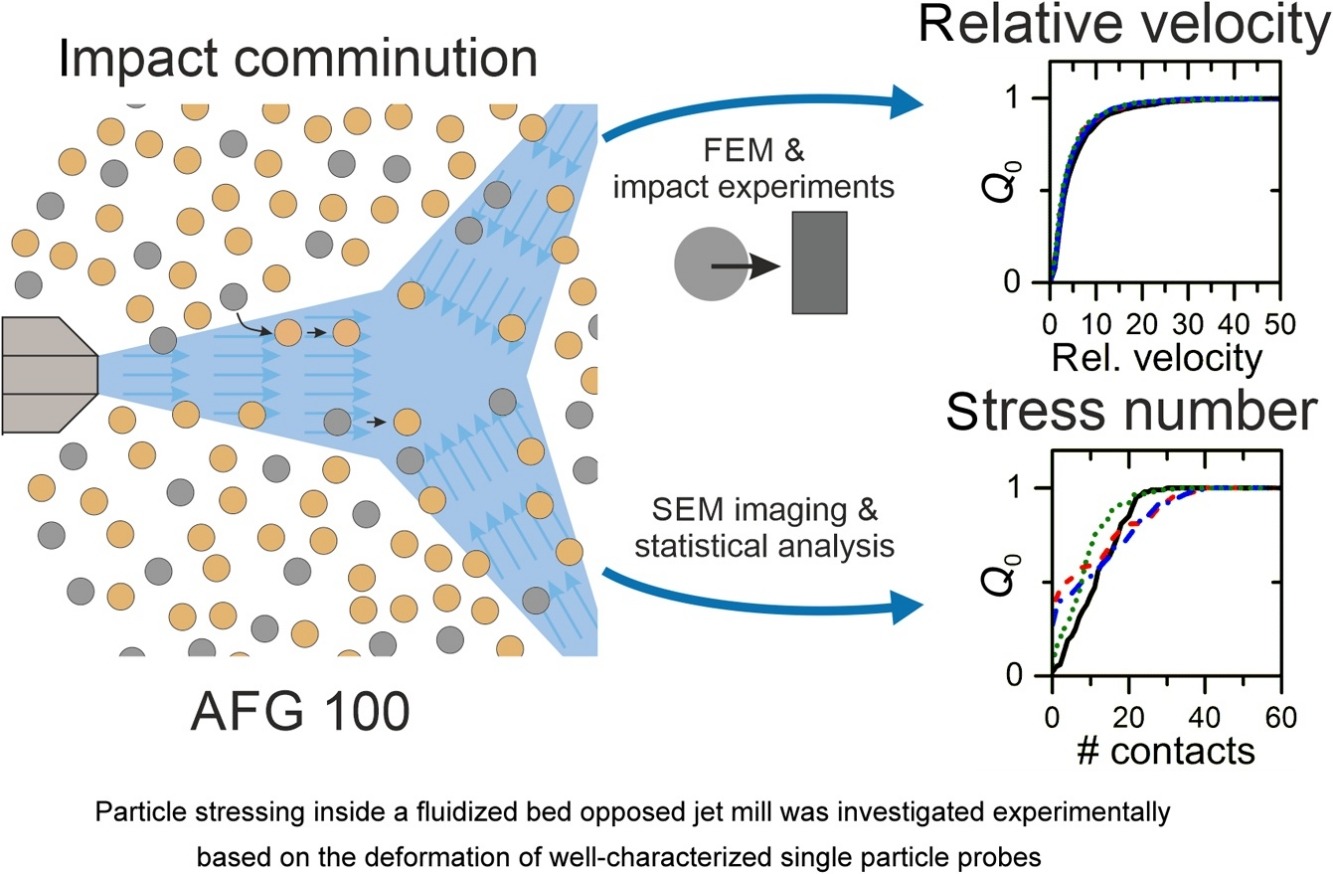

• Characterization of fluidized bed opposed jet mills by single particle probes.

• Determination of relative particle velocities and effective stress numbers.

• Particle image velocimetry for secondary gas injection into a fluidized bed.

Fluidized bed opposed jet mills are capable of meeting the continuously growing demand for contamination-free fine particles. In this type of jet mill, the solid material is entrained and accelerated by expanding gas jets that are focused onto a focal point inside a fluidized bed. The resulting particle collisions induce breakage. The process is affected by the relative particle velocities and the number of particle–particle collisions. Clearly, both quantities are distributed. However, to date, neither relative particle velocities nor collision frequencies in such units have been determined. The present work introduces an innovative method to assess the stressing conditions in jet mills experimentally. To this end, mixtures of glass and ductile metal microspheres were used, with the latter employed in small amounts. Inter-particle collisions between the aluminum and glass spheres lead to the formation of dents on the microparticles. The size and number of these dents are associated with the individual collision velocities and overall collision frequencies. The correlation between dent size and collision velocity was obtained from finite element calculations based on empirical data. The proposed approach was validated using particle image velocimetry during secondary gas injection into a fluidized bed reactor. In this case the effect of the distance between two opposed nozzles was examined. For a lab-scaled fluidized bed opposed jet mill the effects of gas pressure and hold-up were investigated. Relative particle velocities were found to be significantly lower than the gas velocities, while the number of contacts per particle was determined to be extremely high.