- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

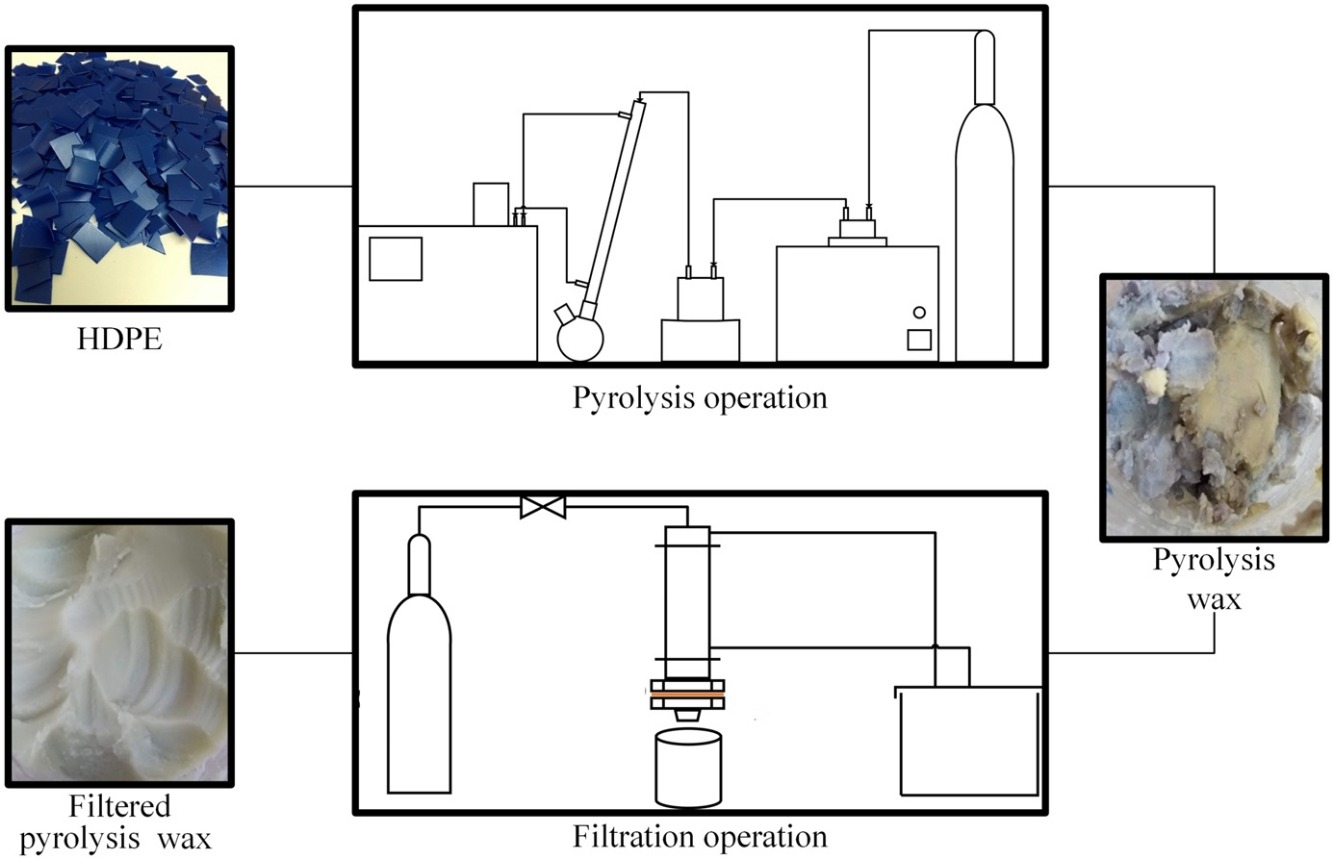

- Nanofiber-coated filter was used for purification of crude and pyrolysis waxes.

- Different filter aids were evaluated for purification of crude and pyrolysis waxes.

- Particle diameter and filter aid shape strongly influences wax filtration.

- Nanofiber-coated filter plus perlite filter aid increased the yield of filtered wax.

- The filtered oily wax became clearer, with impurities practically eliminated.

Wax obtained from the pyrolysis of polyethylene waste can contain inorganic contaminants and must be purified before application. We evaluated different filter aids (perlite, sand, and rice husk ash) for the filtration of a crude wax and a pyrolysis wax through a filter medium that was coated with nylon 6 nanofibers to improve filtration efficiency. We first examined the performance of the filter aids in improving crude wax filtration, with the filtration time, temperature, and pressure held constant at 1 h, 170 °C, and 2.5 bar, respectively. Oily wax was then produced by pyrolysis of high-density polyethylene (HDPE) waste in the temperature range 425⿿475 °C. The best filter aid was perlite, which had a filtrate production rate of 5.47 ÿ 105 m3/h. The highest oily wax yield (87.8%) was achieved at a pyrolysis temperature of 425 °C. The assembly comprising the filter medium coated with nylon 6 nanofibers plus perlite as a filter aid was most suitable for removing impurities from the oily wax generated by the HDPE pyrolysis as it achieved a purification efficiency of 99.9%.