- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

Tianxu Shen a, Xiao Zhu a, Tao Song b, Laihong Shen a *

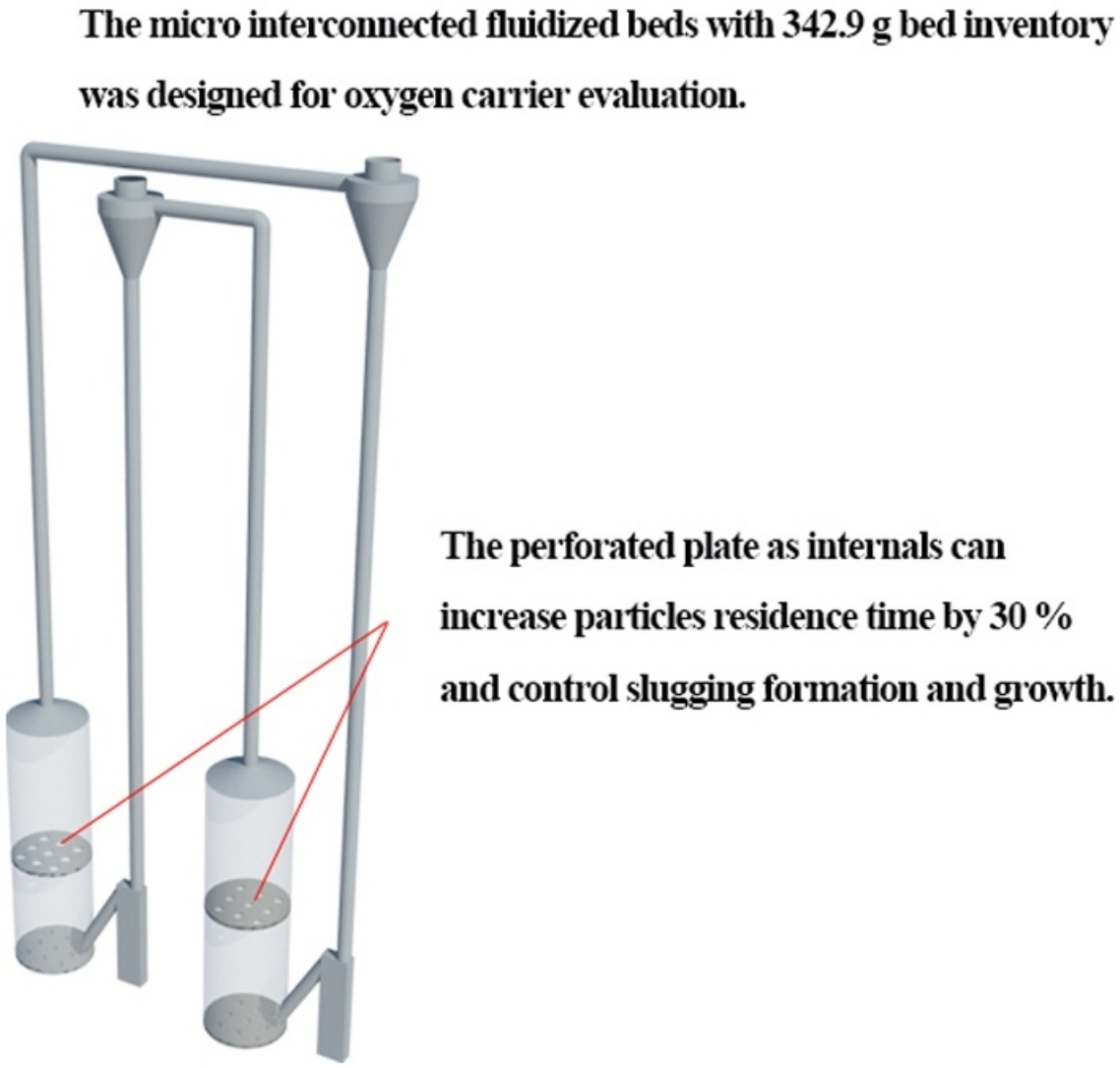

• A micro-interconnected fluidized bed was designed for evaluation of oxygen carrier.

• Flexible and stable fluidization was realized with 342.9 g bed inventory.

• A fitting formula was developed to estimate the upward solid flow in the risers.

• Internal distributors could improve the residence time and fluidization behaviors.

The micro-interconnected fluidized bed (MIFB) was designed to improve the evaluation condition of oxygen carrier, which is difficult to perform in a lab-scale interconnected fluidized bed because of the large demand for bed inventory. The reduction of bed inventory in the MIFB was mainly achieved by the appropriate miniaturization of the reactor size, in which the wall effect and operating flexibility should be taken into consideration. With hematite serving as the oxygen carrier, stable and flexible fluidization could be realized with 342.9 g of bed inventory. Internal perforated plates were arranged in the middle of the reactor to improve gas–solid distribution, which also could restrain the slugging formation and increase the particle residence time by 28.9%. A different fluidization phenomenon was observed in this two-stage reactor in which the particle fluidization was reconstructed in the upper chamber. Throughout 48 h of cold operation, the hematite oxygen carrier attrition rate was evaluated as 0.151 wt.%/h corresponding to 660 h lifetime, where 12.5% of particle attrition was contributed by internal perforated plates. An excellent fitting performance was found between the pressure difference in the risers and the upward particle flow, but the correction factor should be adjusted according to the fluidization flow.