- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

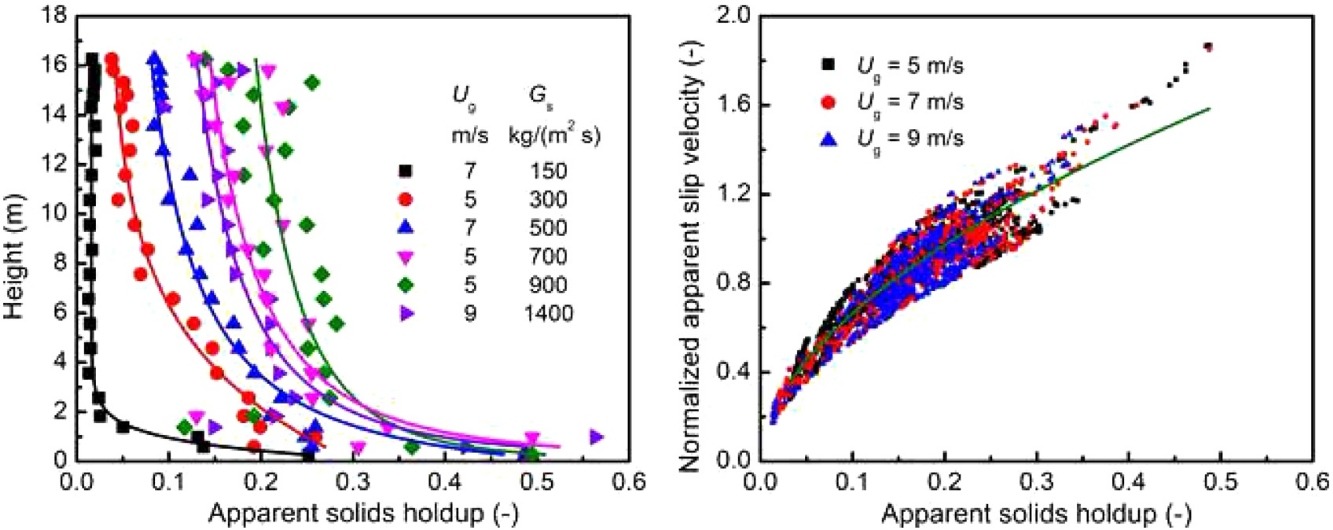

• A solids circulation rate up to 1400 kg/(m2 s) is achieved in an 18-m-high riser.

• Axial profiles of the apparent solids holdup are exponential.

• An apparent solids holdup up to 0.2 is observed along the riser.

• The apparent slip velocity reaches 14 m/s at extremely large Gs.

The axial flow structure in a high-density CFB riser having a height of 18 m is investigated on the basis of pressure measurements. Solids circulation rates reach 1400 kg/(m2 s) at superficial gas velocities of 5–9 m/s and the apparent solids holdup exceeds 0.2, indicating high-density operations have been achieved. The apparent solids holdup increases with the solids circulation rate increasing and/or superficial gas velocity decreasing. Axial distributions of the apparent solids holdup have exponential shapes with denser regions at the bottom and more dilute regions in the upper part. The apparent slip velocity increases with the increasing solids holdup and reaches 14 m/s, showing that there are more opportunities of cluster formation in high-density operation. Furthermore, the apparent slip velocity has a power relation with the apparent solids holdup under a wide range of operating conditions.