- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

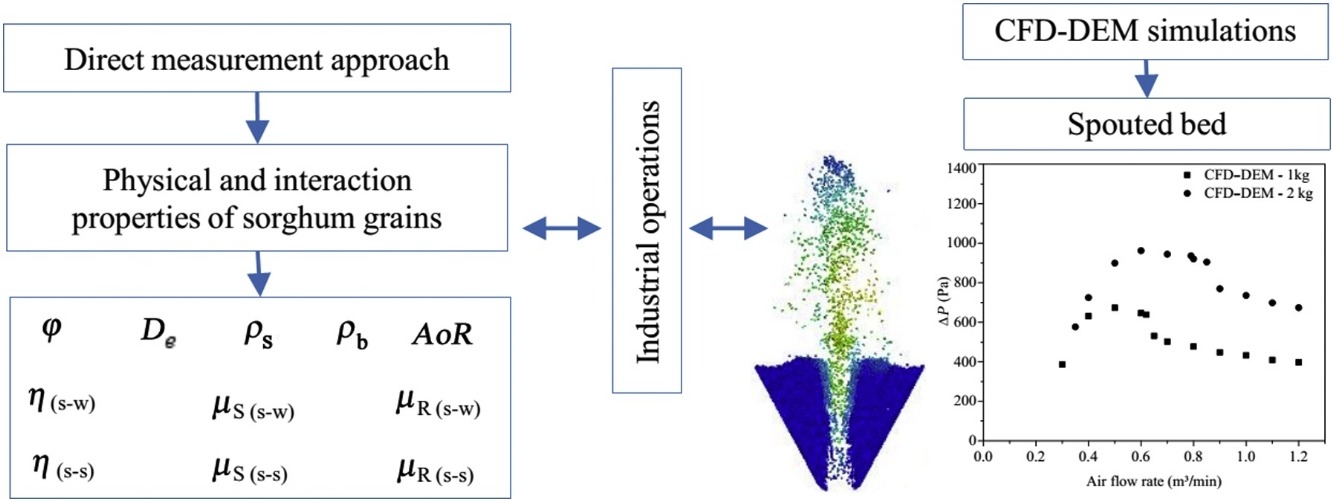

• Conical spouted bed fluid dynamics evaluated by CFD–DEM.

• The measured properties were used as DEM input parameters.

• The minimum spouting velocity was determined using a fluid dynamics curve.

• Small deviations indicated that the flow dynamics can be described by CFD–DEM.

Computational simulation is an important tool for design and improvement of industrial units. Computational fluid dynamics (CFD) coupled with the discrete element method (DEM) has been applied to simulate drying equipment that usually involves gas–solid flow. For reliable results of CFD–DEM simulations, the properties related to the interactions of the material within the industrial equipment, such as the restitution or friction coefficients, must be known. In this study, CFD–DEM was applied to simulate the fluid dynamics inside a conical spouted bed operating with sorghum grains. The physical properties of the particulate phase and the particle–particle and particle–wall interaction parameters were determined by the direct measurement approach and applied to CFD–DEM. The interaction parameters were experimentally determined, including the particle–particle interaction parameters of η = 0.46, μS = 0.79, and μR = 0.70, and the particle–wall interaction parameters of η = 0.56, μS = 0.75, and μR = 0.40. The simulated minimum spouting velocity and characteristic curves were compared with the experimental results. There was good agreement between the simulated and experimental results.