- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

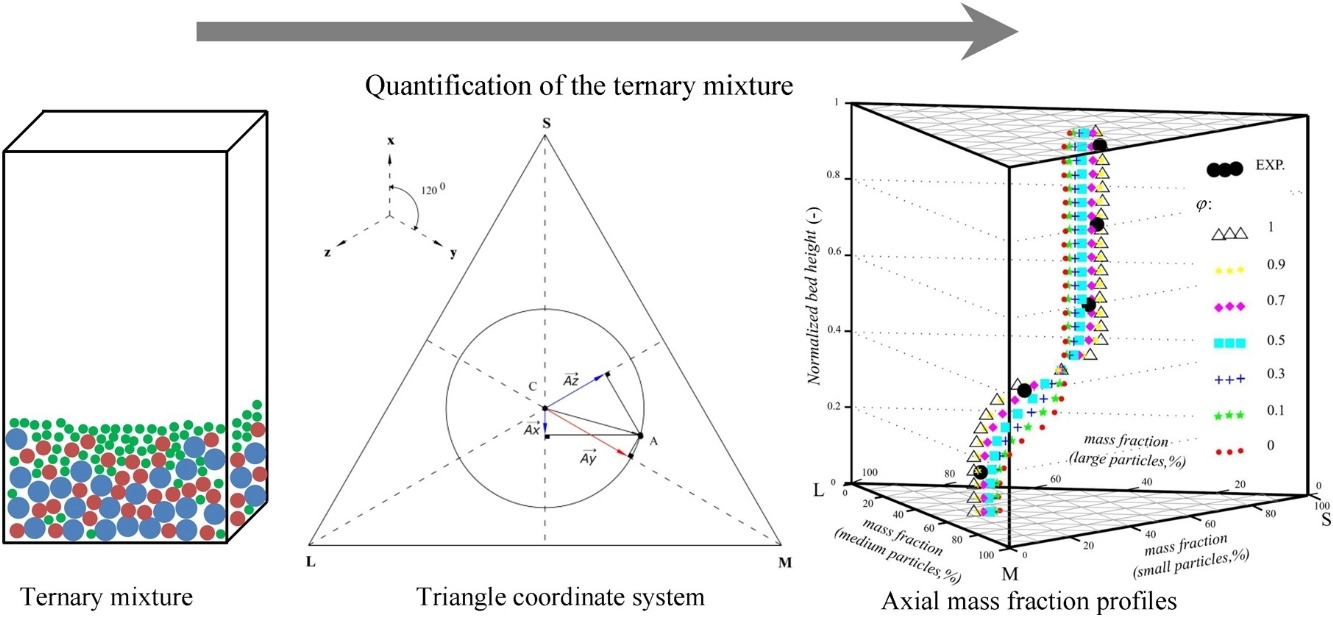

• Size segregation of a ternary mixture in a pseudo 2D fluidized bed was studied.

• Ternary mixture segregation was quantified using triangular coordinates.

• Particle segregation was described using segregation tendency and segregation degree.

• The effects of solid wall boundary conditions on segregation were evaluated.

• The effects of gas velocity on segregation behavior were investigated.

The segregation behavior of a mixture of silica-coated titanium dioxide (TiO2) particles of three different sizes in a pseudo two-dimensional fluidized bed was studied experimentally by the freeze–sieving method and numerically by the multi-fluid model (MFM). Three-dimensional computational fluid dynamics (CFD) simulations were carried out to evaluate the effects of the solid wall boundary conditions on particle segregation in terms of specularity and particle–wall restitution coefficients. The quantitative indexes of segregation tendency and segregation degree were used to determine the axial segregation of the mixture in triangular coordinates. The simulation results revealed that the axial segregation increased with the specularity coefficient, whereas the particle–wall restitution coefficient had a minor effect on axial segregation. Comparison of the simulation results with experimental data showed that the appropriate value of the specularity coefficient used in the CFD model depended on superficial gas velocity. The study of the effects of superficial gas velocity on segregation behavior demonstrated that the greatest segregation was obtained at minimum fluidization velocity and the segregation decreased as the gas velocity gradually increased.