- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

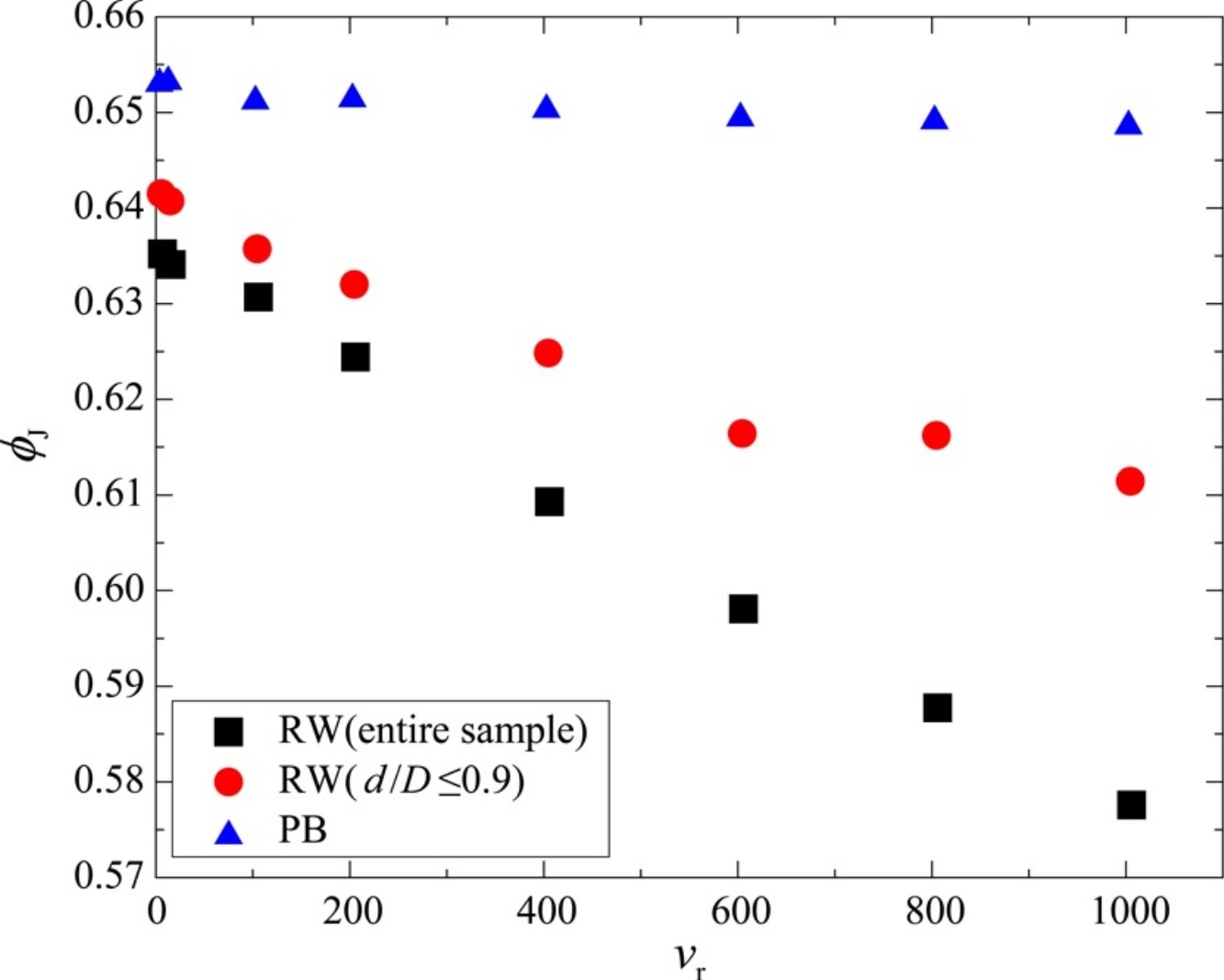

• Critical solid fraction is lower in rigid-wall condition than in periodic condition.

• Critical solid fraction decreases with increasing loading rate.

• Particles cluster closely to the rigid-wall boundaries at high loading rates.

• Force transmission network is pseudo-stable at high loading rates.

The critical solid fraction (ϕJ), which marks the transition between the solid and liquid phases in the jamming diagram, is influenced by several factors. In this study, the dependency of ϕJ on strain rate and boundary conditions is examined through discrete element method simulations considering a frictionless polydisperse granular system. Different approaches are used to determine ϕJ. The observed boundary effect is due to the nonuniform solid fraction distribution induced by the clustering of particles close to rigid-wall boundaries at high compression rates. The solid fraction distribution within the sample in the rigid-wall simulations approaches that in the periodic-boundary simulations as the compression rate decreases. With increasing compression rate, the major force transmission network contains fewer mechanically stable particles and a less stable force transmission network. This causes jamming of the granular assembly at a lower solid fraction. These force transmission networks, however, are fragile and disintegrate quickly upon relaxation.