- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Gas–solid flow pressure drop was computed across thin and thick orifices.

• Combined effects of collisions and pertinent parameters on pressure drop were determined.

• Thick orifices result in higher pressure drop than the thinner ones.

• Orifice thickness is prominent at high Reynolds number and solid loading.

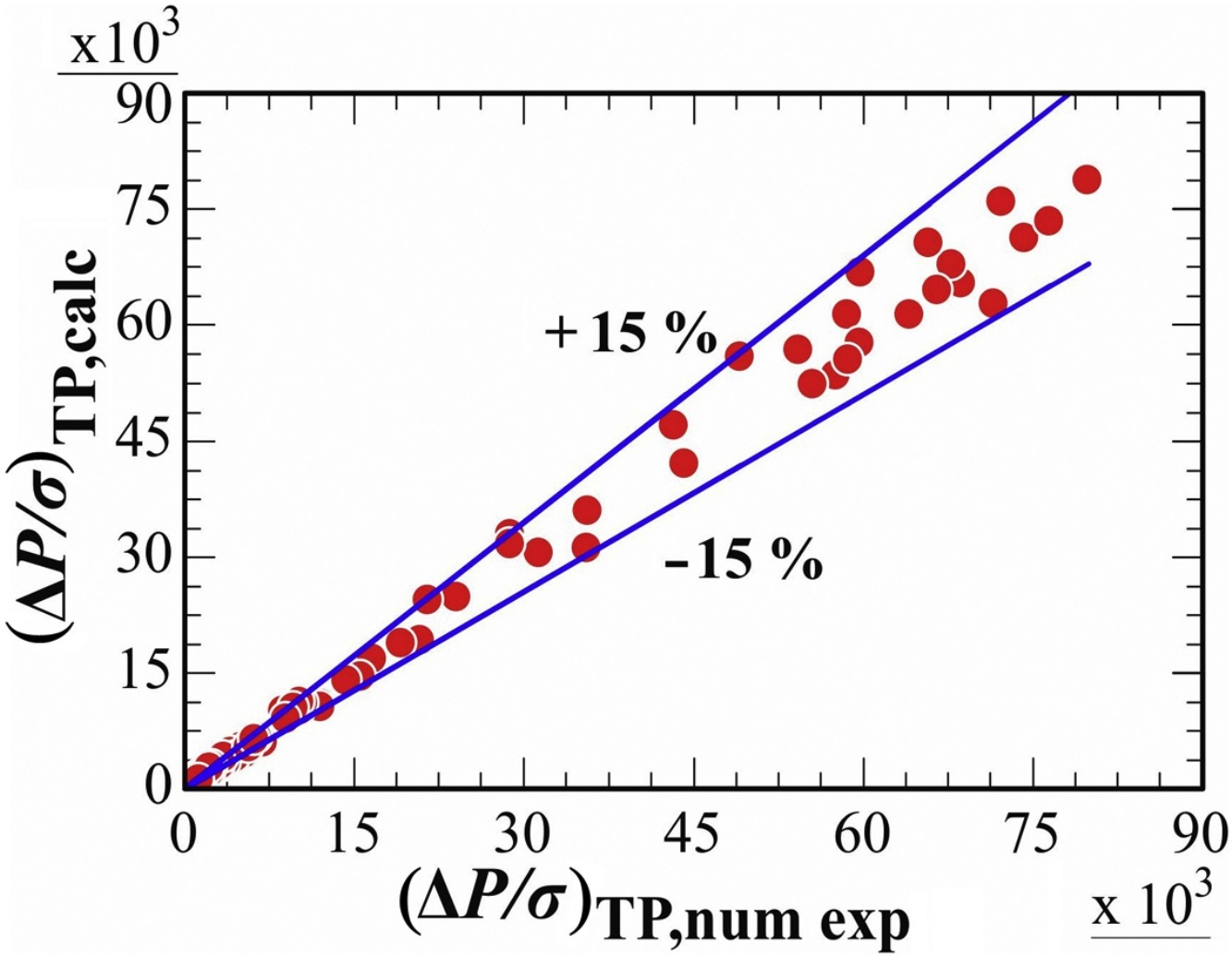

• Two-phase multiplier was proposed for the pressure drop with accuracy within 15%.

The present work deals with the computation of the gas–solid two-phase flow pressure drop across thin and thick orifices for a vertically downward flow configuration at the higher limits of a dilute phase flow situation 0.01  αs, in

αs, in 0.10. The Eulerian–Eulerian (two-fluid) model has been used in conjunction with the kinetic theory of granular flow with a four-way coupling approach. The validation of the solution process has been performed by comparing the computational result with the existing experimental data. It is observed that the two-phase flow pressure drop across the orifice increases with an increase in the thickness of the orifice, and the effect is more prominent at higher solid loading. The pressure drop is found to increase with an increase in the solid volume fraction. An increase in the Reynolds number or the area ratio increases the pressure drop. An increase in the size of the particles reduces the pressure drop across the orifice at both small and relatively large solid volume fractions. Finally, a two-phase multiplier has been proposed in terms of the relevant parameters, which can be useful to evaluate the gas–solid two-phase flow pressure drop across the orifice and can subsequently help to improve the system performance.

0.10. The Eulerian–Eulerian (two-fluid) model has been used in conjunction with the kinetic theory of granular flow with a four-way coupling approach. The validation of the solution process has been performed by comparing the computational result with the existing experimental data. It is observed that the two-phase flow pressure drop across the orifice increases with an increase in the thickness of the orifice, and the effect is more prominent at higher solid loading. The pressure drop is found to increase with an increase in the solid volume fraction. An increase in the Reynolds number or the area ratio increases the pressure drop. An increase in the size of the particles reduces the pressure drop across the orifice at both small and relatively large solid volume fractions. Finally, a two-phase multiplier has been proposed in terms of the relevant parameters, which can be useful to evaluate the gas–solid two-phase flow pressure drop across the orifice and can subsequently help to improve the system performance.