- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

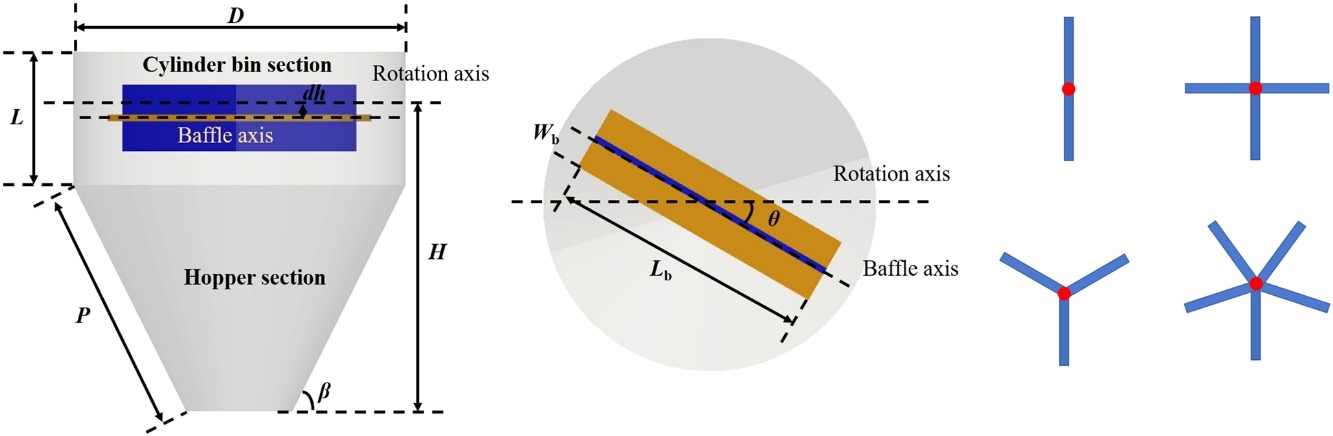

• A DEM simulation with exact description of spheres and sphero-cylinders is performed.

• Inclined short baffles can break the symmetrical flow in the axial direction.

• The asymmetrical flow and convective flow of granules enhance the axial mixing efficiency.

• The segregation caused by the shape discrepancy can be alleviated by inclined baffles.

The mixing performance of a multi-bladed tote blender is investigated using a graphics processing unit-based discrete element method program. The positioning, dimensions, and applicability of the baffles are systematically studied according to the axial mixing efficiency. The results indicate that the novel inclined multi-bladed baffles can break the symmetrical axial granular flow and introduce a more efficient convective flow into the granular mixing in the axial direction of the tote blender. Owing to the joint effects of convective mixing and asymmetrical granular flow, the axial mixing efficiency is increased by a factor of nearly 20. More importantly, the novel baffle placement approach exhibits excellent applicability to different operating conditions, particle shapes, and blender sizes. Additionally, the inclined baffles can prevent the segregation caused by shape discrepancies and improve the mixing homogeneity in the steady state. The novel baffle design is promising for applications in more complex industrial blenders for achieving a high axial mixing efficiency.