- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

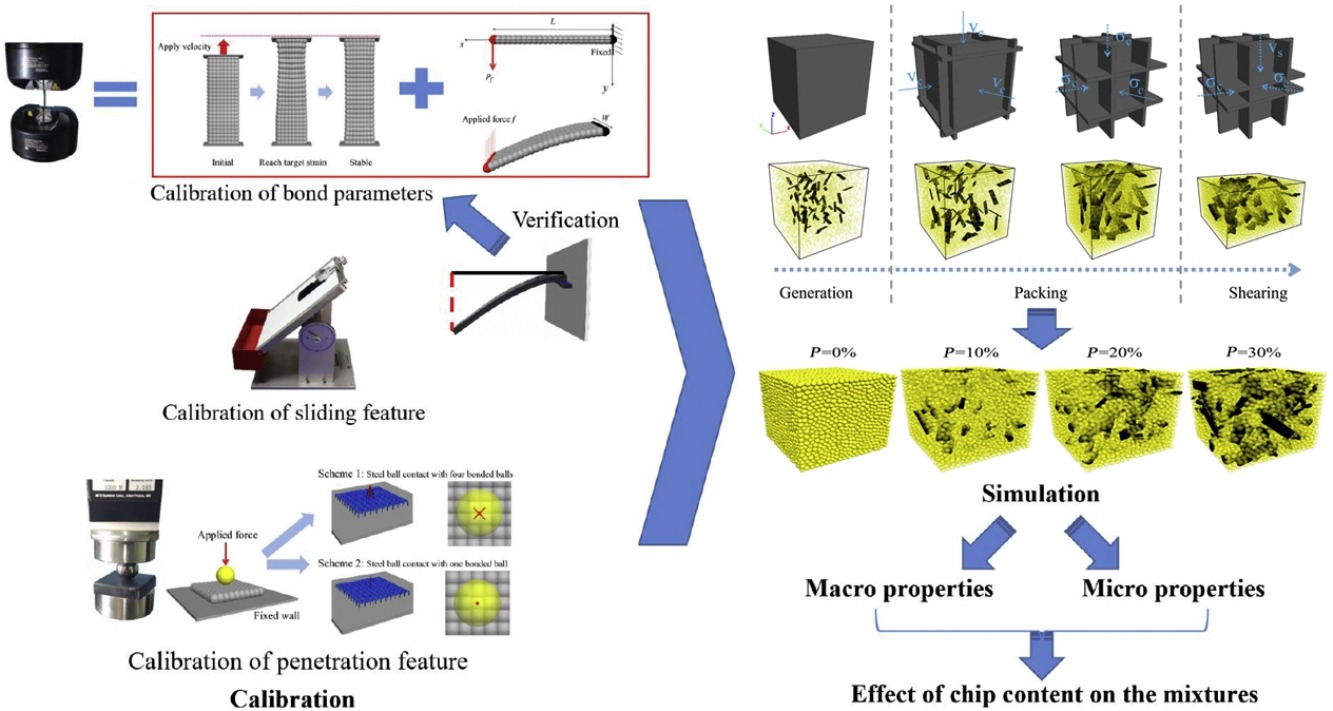

• A soft-chip calibration method is proposed from conventional tensile test results.

• Numerical triaxial tests of rigid grain–soft chip mixture were conducted using DEM.

• The effects of chip content on rigid grain–soft chip mixtures are investigated.

We investigated the macro- and micro-mechanical properties of rigid-grain and soft-chip mixtures (GCMs) through numerical simulations using the discrete element method. We present a novel framework for the discrete modeling of soft chips and rigid grains in conjunction with calibration processes. Several numerical triaxial tests were also performed on GCMs with 0%, 10%, 20%, and 30% volumetric chip contents, P. The simulation results demonstrate that increasing P leads to higher GCM toughness, higher deviatoric peak stress, and higher corresponding shear strain. Higher P also contributes to more volume contraction and less dilation. The friction angles at both the peak and residual state significantly increase with increasing P. In view of the micro-mechanical features, strong contact force chains develop along the loading direction, which results in considerable anisotropy in the peak and residual states. Both the formation of strong force chains and rotation of grains decrease with increasing P, whereas the grain sliding percentage increases. The tensile force is mobilized with shearing and higher P leads to less mobilization of the tensile force. These findings are useful for better understanding the internal structure of GCMs with different soft-chip contents, especially in granular mixture mechanics and geomechanics.