- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

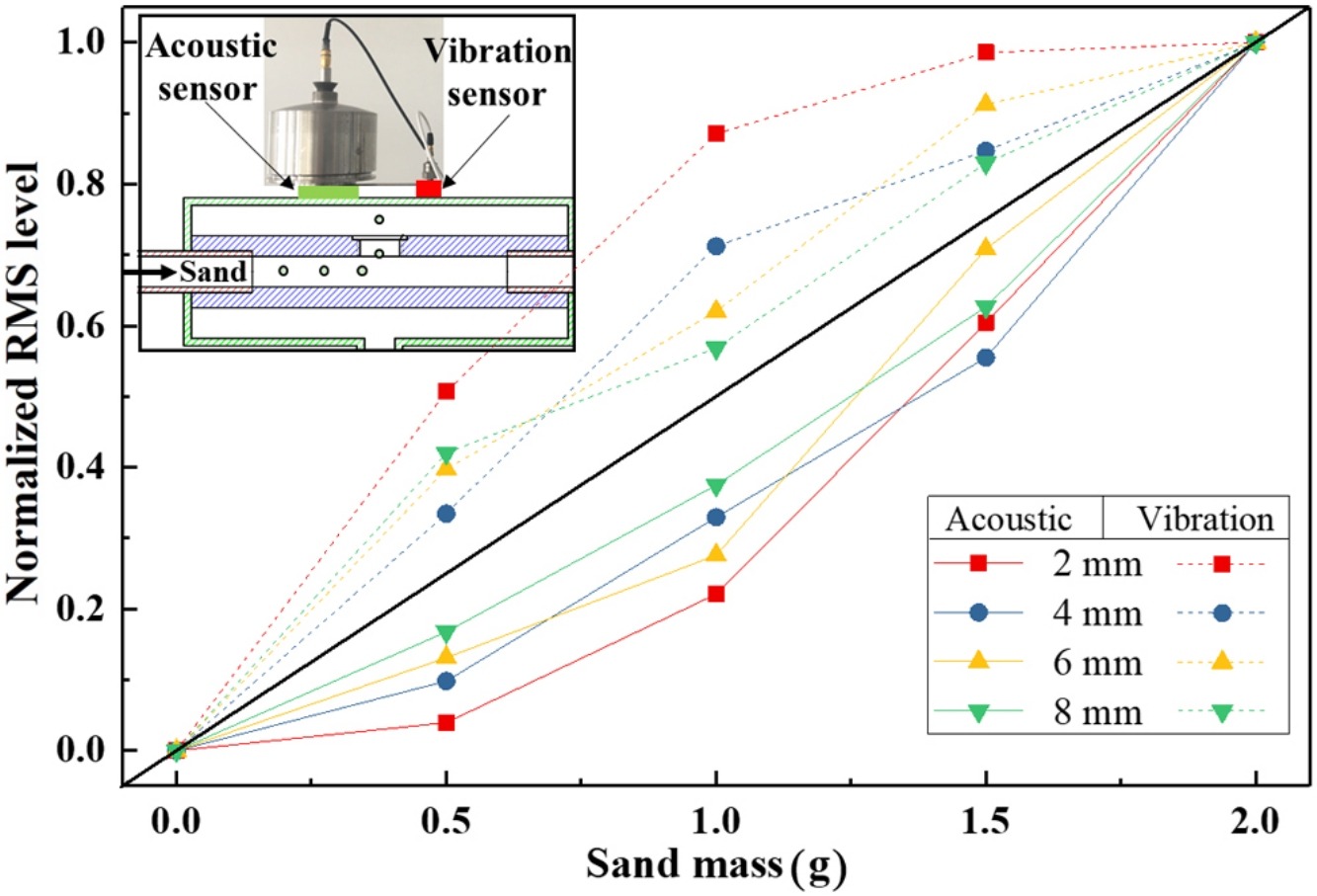

• Vibro-acoustic features of sand leakage from gas flow are analysed by contrast.

• Sand leakage vibro-acoustic feature is differentiated by a time-frequency method.

• A good correlation between the vibro-acoustic features and leak conditions is found.

• Different advantages of the acoustic and vibration sensor methods are presented.

Solid particle leakage detection in double-wall pipes is industrially important, especially in chemical and petroleum engineering. Here, we developed vibration and acoustic sensor approaches for the characterization and comparative study of the applicability of leakage sand particle detection from the flow of gas pipes. A specific wideband vibration sensor and pressure-field microphone were selected to identify the vibro-acoustic characteristics within 50 kHz of the particle leakage. The vibro-acoustic time-behaviours and characteristic frequencies of particle leakage were observed by the time-frequency method. The leakage gas flow noise was verified by coherence analysis and minimized by a digital bandpass and band-elimination filter. Corresponding experiments were performed, and good agreement was found between the release pressures (0.1–0.3 MPa) with different leak sizes (0–8 mm) under different sand masses (120 μm) and vibro-acoustic Root-Mean-Square (RMS) levels. In the comparison of the two methods, the vibration method has a better frequency response for the leakage flow and is good for identifying whether there are particle leaks. The acoustic method has a time behaviour response and is good for establishing the relationship between the particle mass and signals. In addition, the acoustic method has frequency shift features with a better signal to noise ratio. The acoustic method lays the foundation for future work of more complex leakage detection combining the advantages of vibration and the acoustic method.