- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

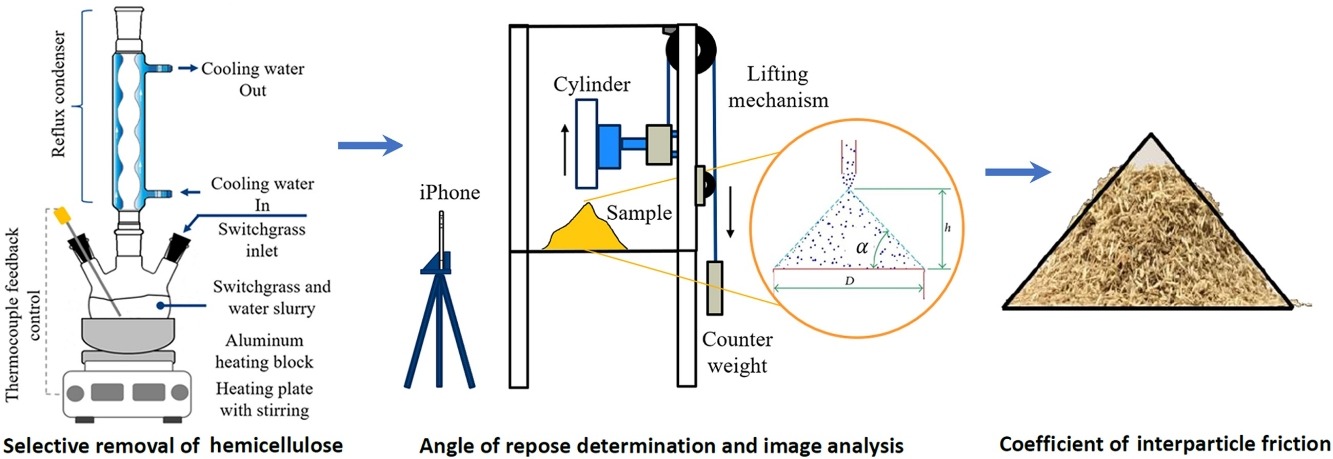

• We selectively removed hemicellulose in a switchgrass sample.

• We investigated the relationship between hemicellulose content and the coefficient of interparticle friction.

• We observed that hemicellulose content and the coefficient of friction are correlated.

Lignocellulosic biomass material sourced from plants and herbaceous sources is considered as a prospective feedstock of inexpensive, potentially carbon-neutral energy. Lignocellulosic biomass is structurally built on cellulose, hemicellulose, and lignin, which are present in varying concentrations based on the feedstock type and play distinct and not well understood mechanical functions in the flow behavior. The frictional characteristics of lignocellulosic biomass particulates influence their flow behavior in biorefineries. Thus, it is important to fundamentally investigate the relative contribution of cellulose, hemicellulose, and lignin to the frictional behavior. However, these three biopolymers are interwoven into a complex matrix in the lignocellulosic biomass, thus making it hard to quantify the contribution of each biopolymer. In this study, we selectively remove hemicellulose from switchgrass and investigate the effects of its diminishing concentration on the coefficient of friction.

We observed that the angle of repose and, therefore, the coefficient of friction for a loose assembly of the control and treated switchgrass samples decrease with decreasing hemicellulose content. This indicates the frictional resistance to flow for biomass particulate assemblies is at least proportional to the hemicellulose content. We also established that the observed changes in the frictional behavior were not due to particle morphological characteristics.