- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

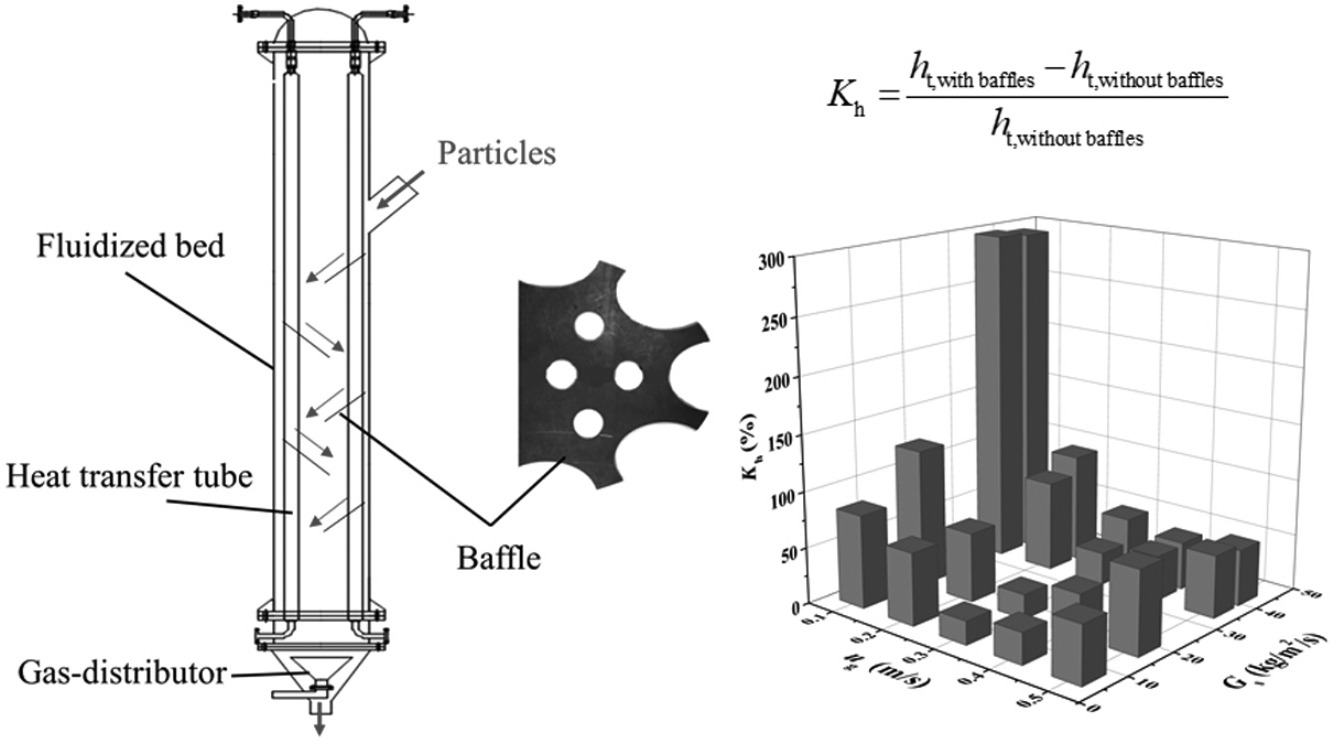

• Wall temperature was used to divide the fluidized bed into different regions.

• Effect of external solid mass flux on bed-to-wall heat transfer was studied.

• Solids heat transfer was found to be bypassed due to poor radial mixing.

• A new baffle design increased the heat transfer coefficient by more than 70%.

Gas–solid fluidized beds have been widely used in heat transfer processes, and so there have been many studies focused on increasing heat transfer in such units. In the present work, a pilot scale cold mode experimental rig was constructed to assess the effects of hydrodynamics on bed-to-wall heat transfer and to investigate various means of enhancing heat transfer in a dense gas–solid fluidized bed with external solid circulation. The experimental results show that heat transfer in the dense region played a dominant role in total bed-to-wall heat transfer, accounting for more than 88% of the total heat transfer load. Heat transfer could be lowered as a result of solids bypass that occurred because of external solids circulation, but this effect was weakened by the radial mixing of particles. The heat transfer characteristics identified in this study indicate that a specially designed baffle can be used to enhance bed-to-wall heat transfer. After installing such baffles in the fluidized bed test structure, a 70% increase in the total heat transfer coefficient was obtained.