- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

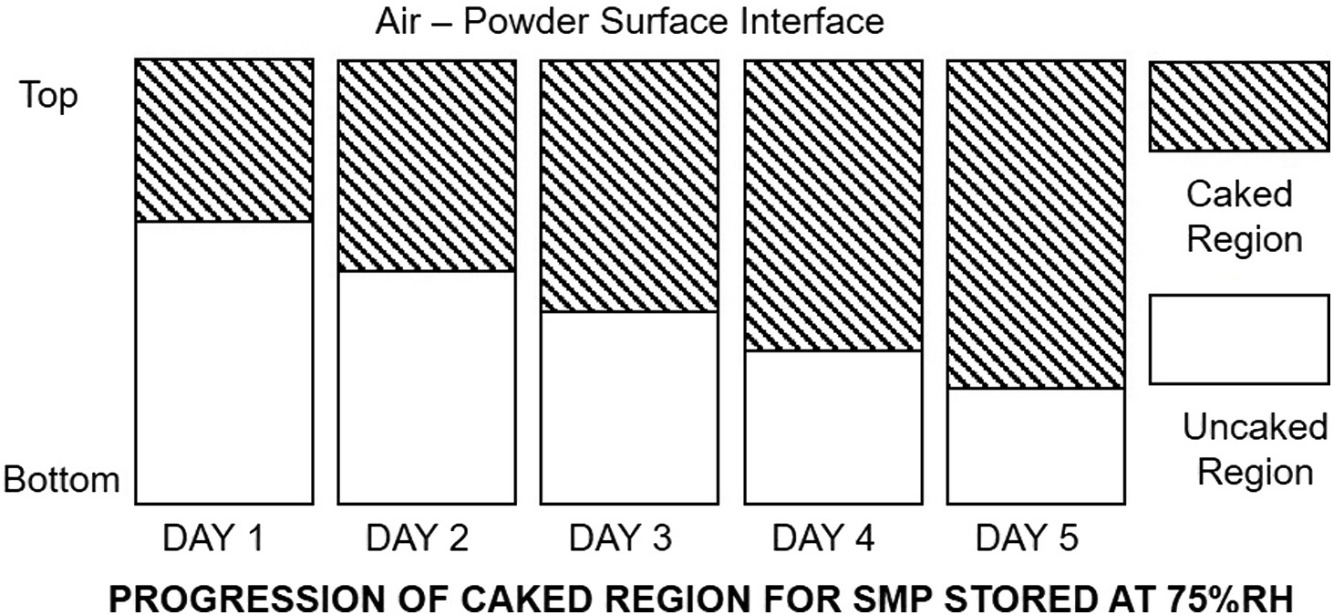

• Moisture absorption may result in non-homogenous caking.

• Homogeneous and non-homogeneous crusting can be assessed using powder rheology.

• Powder cakes can strengthen even after being removed from high humidity conditions.

• More accurate measures of different types of caking are necessary.

Whilst caking occurs via several different mechanisms, absorption and migration of moisture is frequently the most dominant mechanism within the food and pharmaceutical industry. Fully understanding the propensity to cake is important for minimising down-stream process issues, however most characterisation techniques assume that moisture induced caking occurs homogenously through the sample resulting in a uniformly caked powder bed. In this study, the effect of moisture induced caking on powder flowability was investigated using powder rheology. Several materials, including skimmed milk powder (SMP) and sulphated methyl ester (SME) were stored for several days under controlled humidity conditions. The flow energies, a measure of the resistance to flow, were measured at 24 h intervals using an FT4 Powder Rheometer. As the energy is measured as a function of the bed height, variations in the powder bed are also captured. The results demonstrated that caking does not always occur uniformly, instead a caked region (or crust) forms at the air-powder interface and then progresses through the powder bed. Furthermore, the strength of this caked region was shown to increase over several days before stabilising.