- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

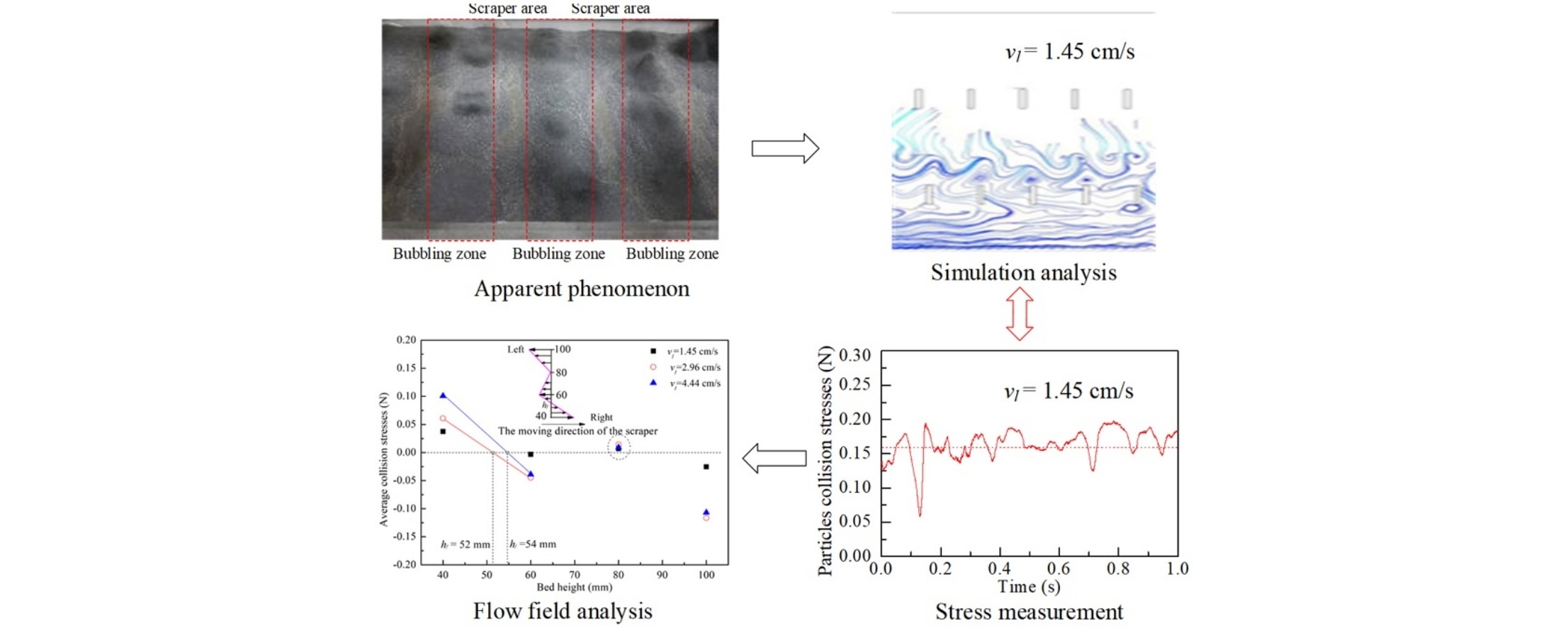

• The hydrodynamics of a fluidized bed equipped with a scraper were analyzed theoretically.

• The streamline of the bed flow field was studied by simulations.

• The collision stresses of medium particles with the scraper were measured.

• The flow field of the fluidized bed equipped with a scraper was summarized.

Continuous gas–solid separation fluidized beds are one of the most widely used practical operation units for the dry separation of coal in China, particularly in Northwest China, and they can effectively promote the efficient and clean utilization of raw coal. In a continuous gas–solid separation fluidized bed, the bed flow field is the concrete manifestation of the fluidization characteristics. However, the complexity of the flow field increases under the action of a moving scraper. In this study, a combination of computational fluid dynamics (CFD) simulations and experimental measurements was used to study the changes in the flow field of a fluidized bed. The results showed that when the scraper moved, the local flow field (mainly characterized by the movement of medium particles) near the scraper was affected not only by the common airflow or bubbles, but also by the lateral driving force of the scraper. When the scraper speed was vl < 6.0 cm/s, it reduced the frequency of the formation of large bubbles and alleviated the random fluctuation of the nearby particle collision stress signals, which improved the fluidization stability of the bed. Additionally, the movement of the scraper affected the global flow field. The flow field shifted to the right near the scraper, with the direction of the scraper movement, while the flow field exhibited a leftward trend on the surface of the bed, accompanied by some vortices, in the middle and lower parts of the bed. Additionally, the critical height of the area, directly affected by the scraper, increased from 52 to 54 mm with an increase in its operating speed from vl = 2.96 cm/s to vl = 4.44 cm/s, respectively. This provides a theoretical basis for further understanding the hydrodynamic characteristics of fluidized beds.