- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

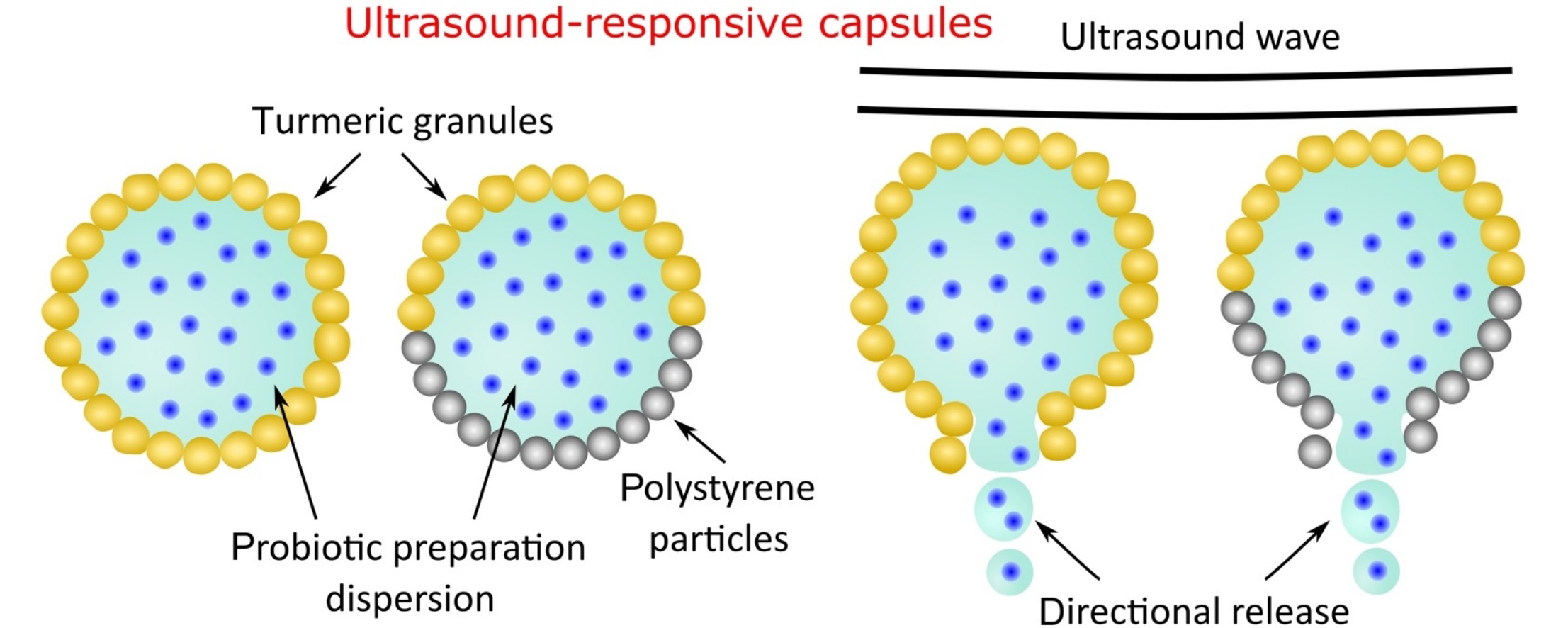

• Capsules with a shell made of a monolayer of fine turmeric granules were produced.

• Low-intensity and high frequency ultrasound triggered payload release from capsules.

• Ultrasound-induced liquid cargo liberation was controlled and unidirectional.

• Mechanical properties of Janus shell regions affect the course of content liberation.

The scientific interest in capsules with the shell composed of fused microparticles is still growing due to a large number of practical applications. Well-designed capsules should ensure the safe cargo delivery and facilitate its controlled release on demand. The biocompatibility and biodegradability are additional essential features of structures intended for biomedical use. This paper presents two kinds of ultrasound sensitive capsules: the first type with the homogeneous shell made of a monolayer of fine turmeric granules, and the other with Janus shell composed of two different materials i.e. turmeric granules and synthetic polystyrene particles. We demonstrated that plane ultrasonic waves with low intensity and high frequency and also focused ultrasound can act as a trigger for smooth liberation of a liquid cargo, in our case, the dispersion of probiotic preparation. The ultrasound-induced puncture of the shell was followed by unidirectional and controlled release of encapsulated payload. In case of Janus structures, in addition to sonication time and ultrasound frequency, distinct mechanical properties of two shell regions also influenced the course of content liberation process. We expect that the use of natural material such as turmeric granules for the formation of the shells of the ultrasound-responsive capsules can further increase the range of their potential applications.