- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

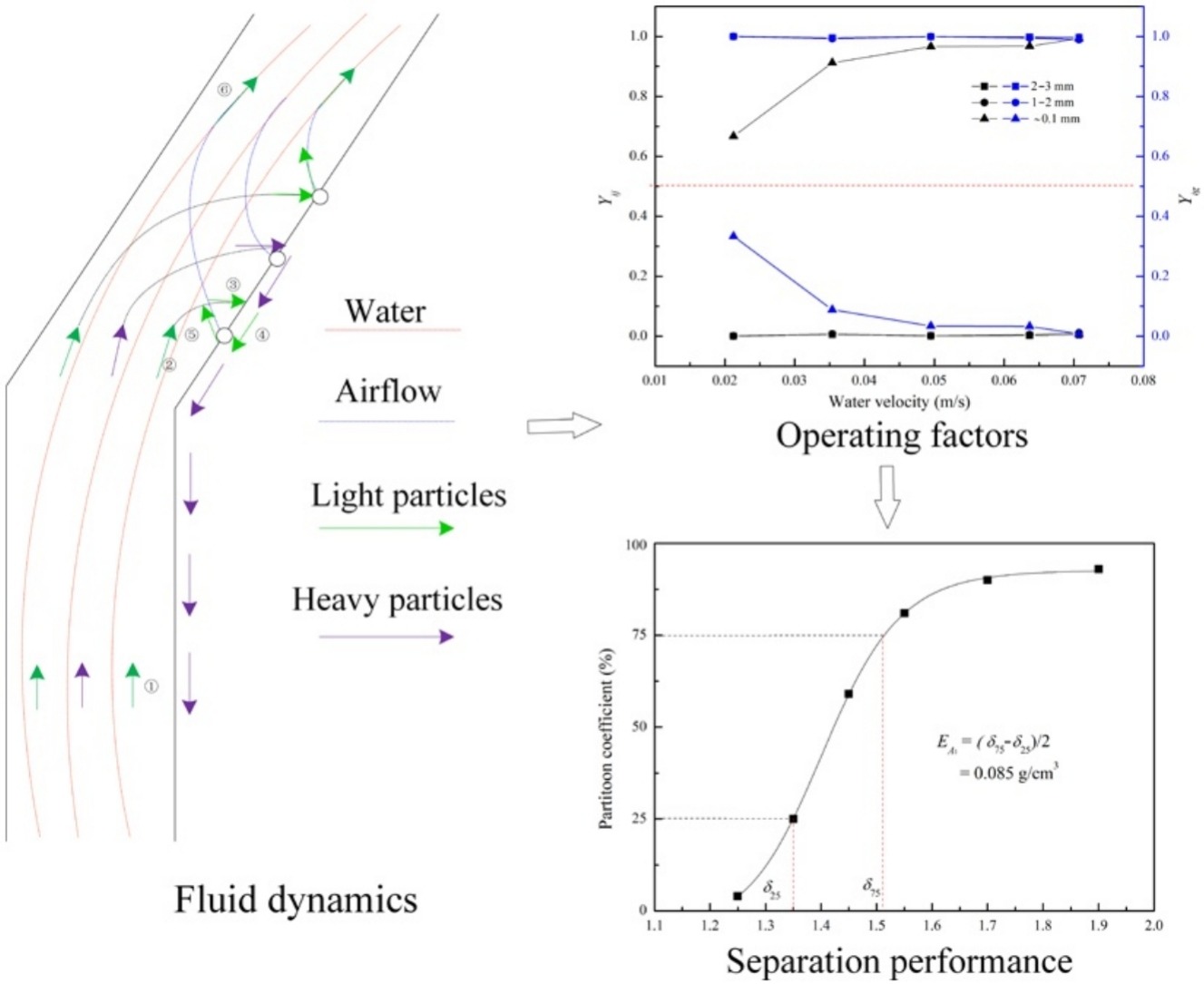

• A method to improve a fluidized bed for fine coal separation was proposed.

• The inflatable-inclined liquid–solid fluidized bed (IILSFB) was developed.

• Fluidization characteristics and separation performance were analyzed.

• Under optimal working conditions, the IILSFB has good separation performance.

To improve the adaptability of fluidized beds for fine coal separation, a new type of liquid–solid fluidized bed was constructed, i.e., the inflatable-inclined liquid–solid fluidized bed (IILSFB). A combination of simulation analysis and separation experiments was used to analyze the fluidization characteristics and separation performance of the IILSFB. The results showed that there was upflow and downflow in the fluidized bed. The upflow was mainly composed of water flow, followed by light and heavy particles; on the other hand, the downflow was caused by the backflow of heavy particles that settled at the inclined section. In addition, the light particles that settled at the inclined section could return to the rising water flow under the action of secondary airflow. As the water velocity, separation time, and secondary gas velocity increased, the comprehensive separation efficiency of fine coal in the fluidized bed improved, while the value decreased as the feed quantity increased. This also indicated the order of importance for these four factors, i.e., water velocity, separation time, feed quantity, and secondary gas velocity, on fluidisation. Furthermore, the comprehensive separation efficiency of 0.1–1 mm fine coal varied significantly with various factors, while that of ∼0.1 mm and 1–3 mm fine coal was always at a low value. In the latter case, the classification process of the size fraction was significantly better than the separation process in the fluidized bed. Under optimal working conditions, an IILSFB was used to separate the fine coal (0.1–1 mm). The yield of clean coal was 37.95% with an ash content of 12.11%, and the possible error was 0.085 g/cm3, indicating that the IILSFB had good separation performance for 0.1–1 mm fine coal.