- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

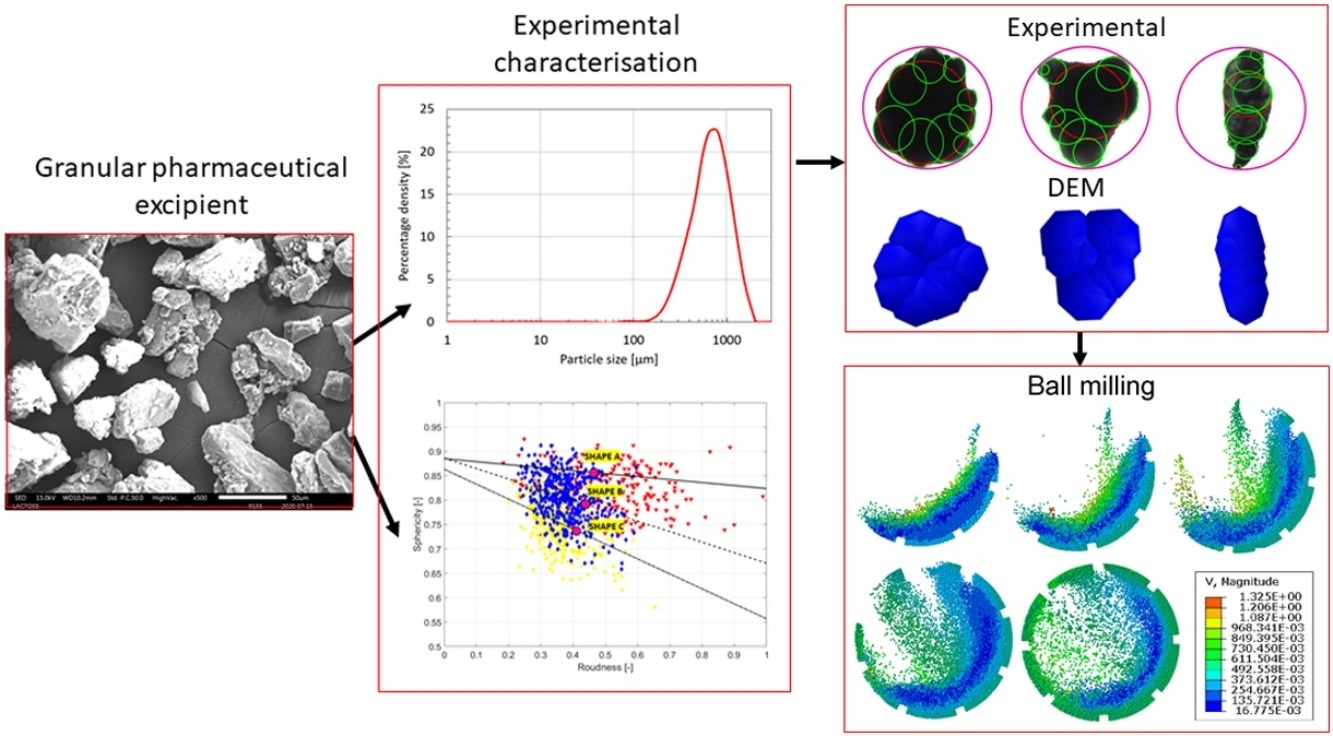

• Ball milling of pharmaceutical granules was numerically investigated.

• The effect of milling speed on the fragmentation of DEM granules was examined.

• A discrete element model was developed to predict breakage of the granules.

• The clustering method was employed to identify the number and size of fragments.

Ball milling is widely used in industry to mill particulate material. The primary purpose of this process is to attain an appropriate product size with the least possible energy consumption. The process is also extensively utilised in pharmaceuticals for the comminution of the excipients or drugs. Surprisingly, for ball mill, little is known concerning the mechanism of size reduction. Traditional prediction approaches are not deemed useful to provide significant insights into the operation or facilitate radical step changes in performance. Therefore, the discrete element method (DEM) as a computational modelling approach has been used in this paper. In previous research, DEM has been applied to simulate breaking behaviour through the impact energy of all ball collisions as the driving force for fracturing. However, the nature of pharmaceutical material fragmentation during ball milling is more complex. Suitable functional equations which link broken media and applied energy do not consider the collision of particulate media of different shapes or collisions of particulate media (such as granules) with balls and rotating mill drum. This could have a significant impact on fragmentation. Therefore, this paper aimed to investigate the fragmentation of bounded particles into DEM granules of different shape/size during the ball milling process. A systematic study was undertaken to explore the effect of milling speed on breakage behaviour. Also, in this study, a combination of a density-based clustering method and discrete element method was employed to numerically investigate the number and size of the fragments generated during the ball milling process over time. It was discovered that the collisions of the ball increased proportionally with rotation speed until reaching the critical rotation speed. Consequently, results illustrate that with an increase of rotation speed, the mill power increased correspondingly. The caratacting motion of mill material together with balls was identified as the most effective regime regarding the fragmentation, and fewer breakage events occurred for centrifugal motion. Higher quantities of the fines in each batch were produced with increased milling speed with less quantities of grain fragments. Moreover, the relationship between the number of produced fragment and milling speed at the end of the process exhibited a linear tendency.