- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Fluidization of biomass pellets was achievable even at higher loading of up to 30%.

• Non-pelletized biomass fluidized only up to 20% weight percent in silica sand.

• Bubble size and motion played major role in increased biomass fluidization.

• More biomass materials observed towards bed center at low fluidization velocities.

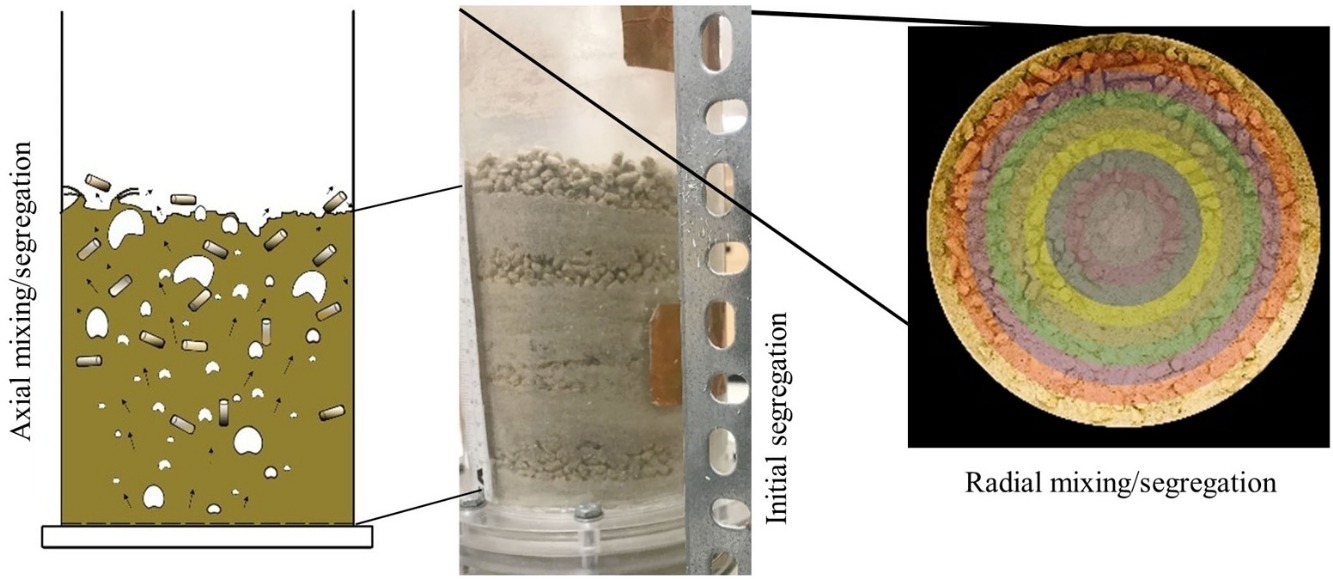

In this work, mixing and segregation of binary mixtures involving biomass materials in a fluidized bed was experimentally investigated. A frozen bed method was employed to investigate both axial and radial distribution of biomass particles in silica sand. Three different biomass materials were studied: willow sawdust, pelletized soy and oat hull materials. Biomass loading investigated ranged from 5% to 30% by weight. The extent of mixing for each of the biomass composition was investigated using Lacey’s mixing index which is based on the standard deviations of the sample at different axial positions in the bed. The radial composition was also investigated by means of digital imaging analysis using a high-resolution digital camera. The experiments revealed the differences in the extent of particle distribution for pelletized biomass materials vs non-densified materials as a result of differences in particle size, density and importantly, the particle shape of the materials utilized. The results showed an increase in the extent of mixing as the fluidizing velocity increased for both pellet materials while the mixing index for sawdust decreased beyond a loading of 20%. With an increase in biomass loading, an increase in mixing index was found for the two pellet materials. A similar trend was observed for sawdust at the lower loading level. However, the mixing index started to decrease at higher loading level beyond 20%. The results greatly contributed to the understanding of the hydrodynamics of binary and multicomponent mixtures involving biomass materials, especially pelletized materials in fluidized beds.