- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Three-dimensional simulations of turbulent two-phase flows were carried out.

• Characteristics of the fluidized bed for tapered bioreactors were analyzed.

• The resulting fluidization curves showed good agreement with experimental data.

• The turbulence in fluid flow is more intense than bioparticles turbulence.

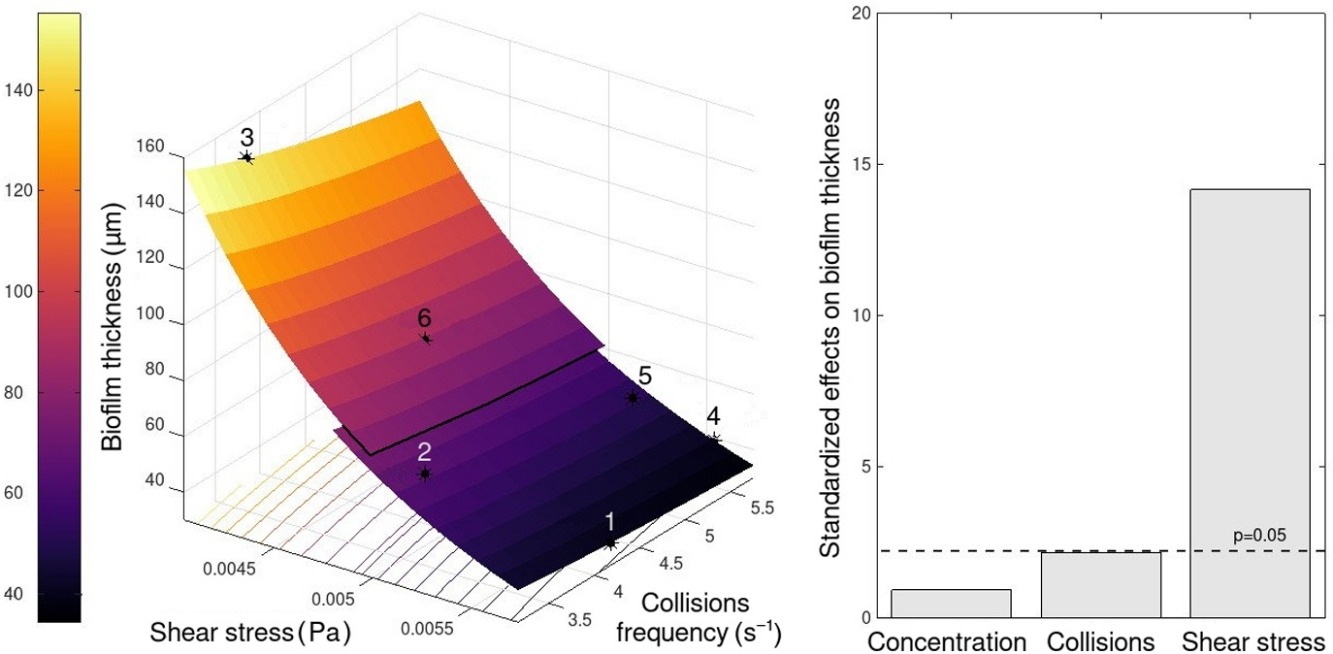

• Bioparticles collisions and shear stress effects on biofilm thickness were modeled.

Fluidized beds in tapered geometries provide advantages such as a broad range of optimum operating conditions. However, the dynamics of the flow inside these bioreactors is significantly more complex, as they promote non-uniform bioparticles distribution. To this end, the CFD technique can give a detailed description of the flow in the bioreator. Hence, the aim of this work is to assess the influence of the hydrodynamic on the steady-state biofilm thickness through numerical simulations of liquid–solid fluidized bed. Two geometries of tapered bioreactors in the operating conditions used to develop biofilms. Simulations were run to solve the two-phase RANS equations using the open-source software OpenFOAM in transient-state. The SST k − ω model was used to estimate the turbulent features of the flow. Velocity and bioparticles distribution inside the reactor were analyzed for different inlet velocities, while bioparticles collision frequency and shear stresses were evaluated for various operating conditions. The comparison between the turbulent kinetic energy and the granular temperature indicated that the fluid flow is more turbulent than the bioparticles movement. The hydrodynamics influence on the steady-state biofilm thickness was assessed, and results led to the conclusion that biofilm is more sensitive to hydrodynamic shear stress than bioparticles collisions.