- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

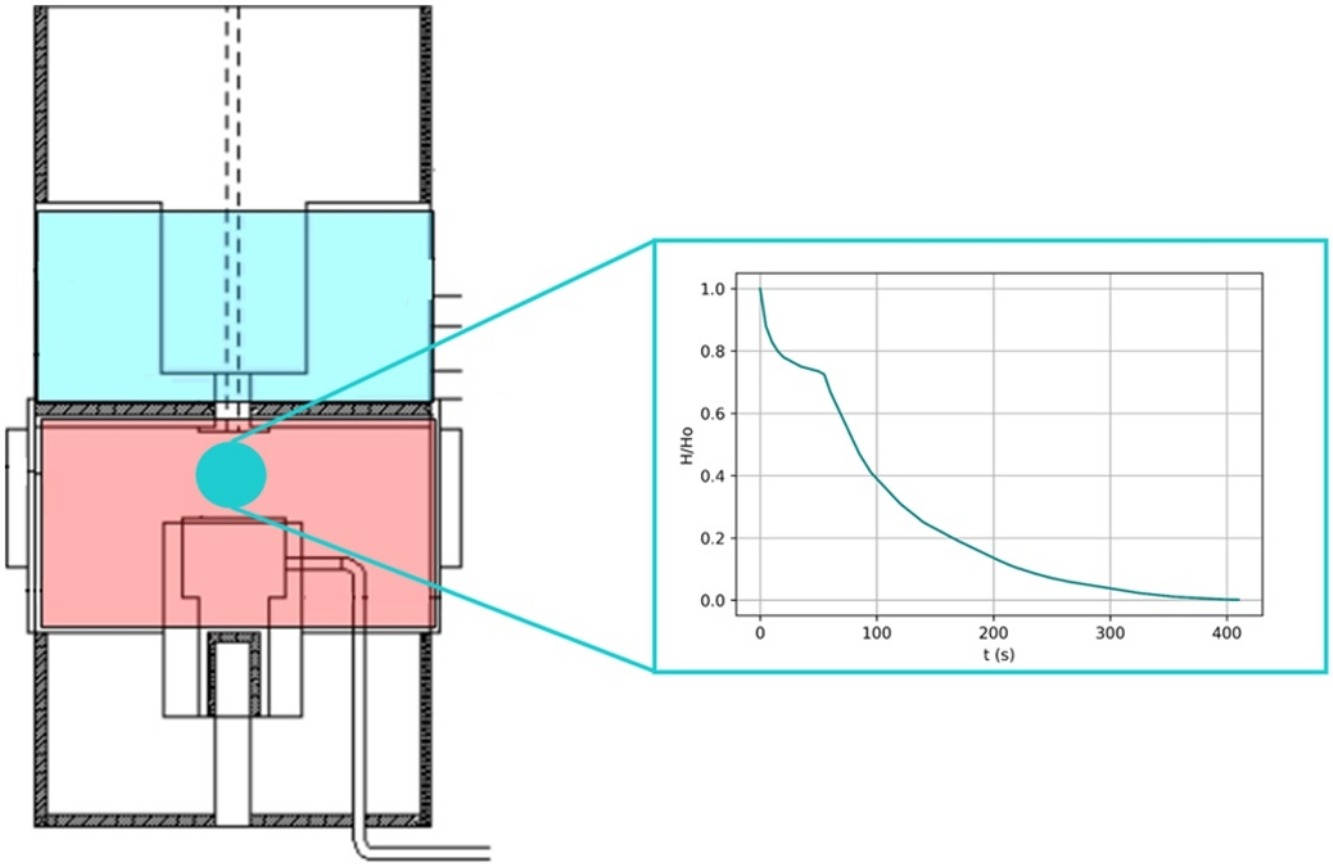

• Three stages are observed: free diffusion, diffusion governed by crust and boiling.

• A multi-stage first principles-based model has been developed.

• Droplets show a low porosity crust that governs drying during a second stage.

• The second stage represents up to 25% of the total drying time in detergents.

• No bursting is observed since boiling is in free convection regime.

This study evaluates the single droplet drying (SDD) of detergents. Experimental data are used to validate a theoretical multistage model. The experiments are carried out in an acoustic levitator analysing six different detergent formulations at 393 K. The work is completed by developing a model based on conservation equations. The model is composed of the three stages observed in the drying curve. In the first stage, an external surface drying stage occurs until the surface is saturated and the crust is formed. In the next stage, the drying rate is governed by diffusion through the pores. At the same time, the particle heats up until boiling conditions are achieved in the core of the particle. At this point, the third stage begins. In the final stage, the droplet core is in boiling conditions which are governed by the pressure drop through the crust and the concentration of salts. This model has been evaluated for the different formulations being flexible to predict the drying of different mixtures with good accuracy.