- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

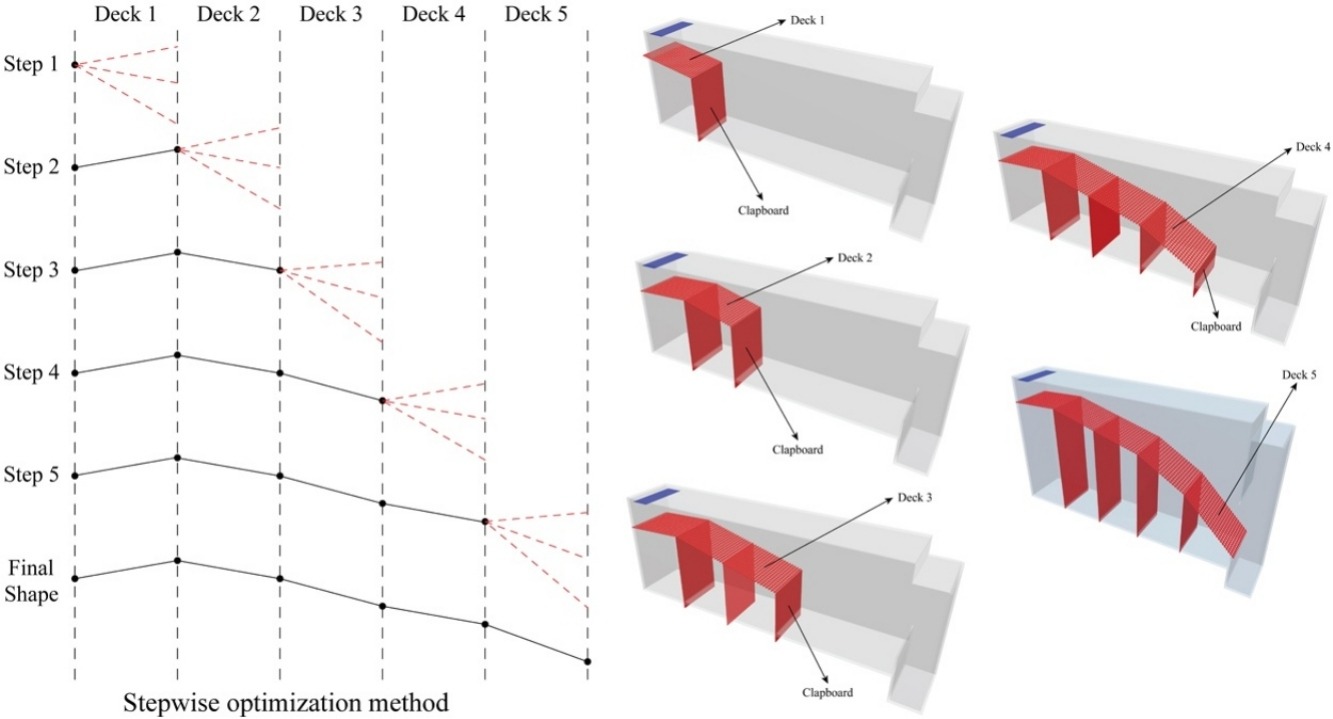

• Stepwise optimization method that strictly optimizes the screen surface shape.

• Presentation of a new curved screen having five decks.

• Inclination angles of the screen decks of −2.5°, 15°, 15°, 30°, and 45°.

• Verification of superior screening efficiency of the new curved screen by 8%–10%.

Screening is a technique that is extensively adopted for the separation of discrete materials according to particle characteristics such as size and shape. Wide application of the discrete element method has sparked much research on the vibrating screen, which is a screening apparatus having a specific vibration mode. The shape of the screen surface is a critical factor affecting the sieving performance of the vibrating screen. In this paper, a stepwise optimization method is employed to optimize the screen surface shape of the vibrating screen in discrete element modeling to obtain a high screening efficiency and large processing capacity simultaneously. Adopting this optimization method, a new curved screen with five decks having various inclination angles is presented. Numerical simulations and prototype experiments are conducted to verify the superior sieving performance of the new curved screen. Experimental results clearly show that the new curved screen greatly outperforms three commonly used screens in terms of sieving performance. The conclusions and methodologies of this work will benefit the design and improvement of vibrating screens.