- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

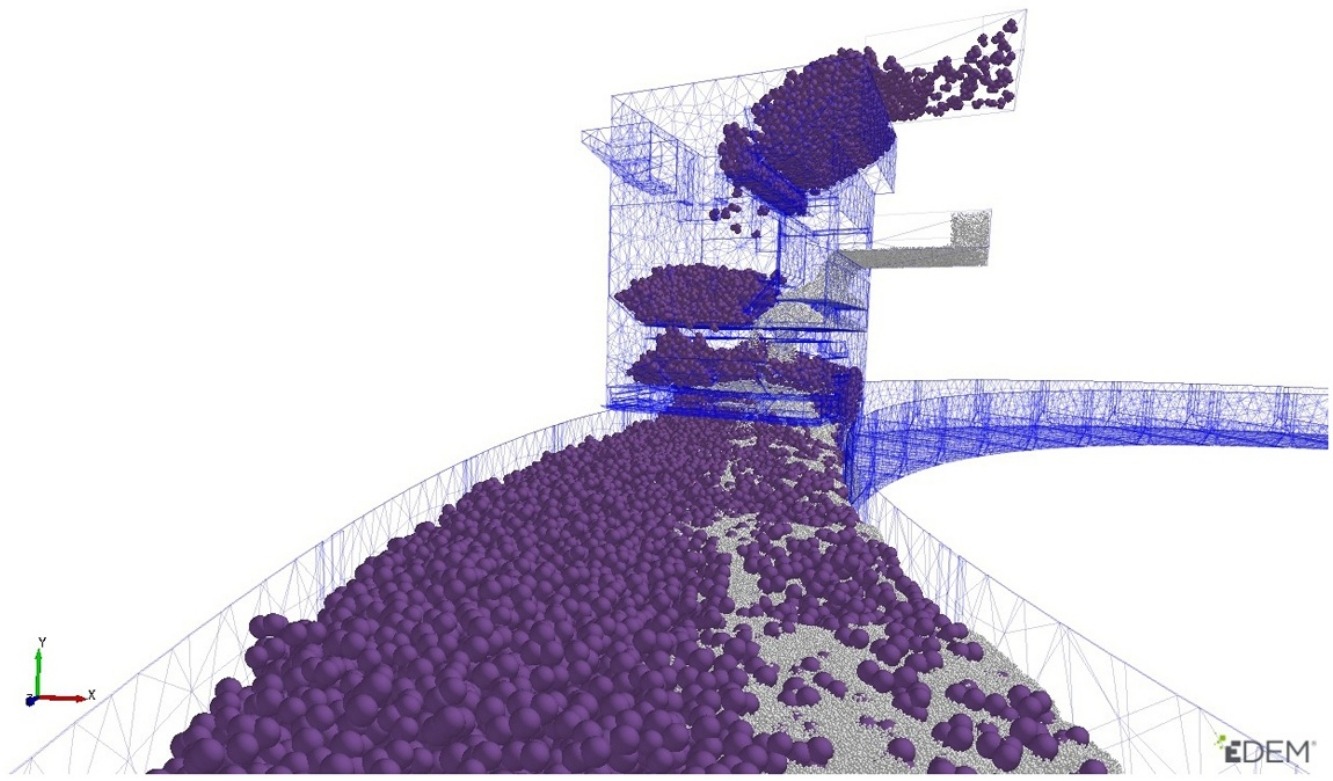

• Measures of segregation at the charging system exit are qualitatively reproduced with a DEM model.

• Segregation patterns are not affected by the different sizes used for fine particles in the model.

• A small chute filling ratio is detrimental to process efficiency regarding particles distribution.

This paper presents the simulation of material flows in the large-scale charging chute of Fos-Sur-Mer sinter cooler plant by using three-dimensional Discrete Element Method (DEM). As a result of granular flows in the chute, segregation patterns are formed at the charging exit. The sinter material is modelled as dry particles and their size distribution in the simulation is larger than in the reality to keep the simulation in a reasonable run time. Suitable calibration tests are performed to specify the DEM contact parameters in order to replicate the behavior observed during experiments with the virtual sinter particles. The DEM model is found to be in good agreement with a segregation measurement. A sensitivity analysis using different particle sizes shows that the segregation patterns are not affected by the different sizes used for fine particles. Furthermore, the filling ratio in the charging system is varied in the model and shows that a high filling ratio leads to less segregation when exiting the charging chute. The DEM model is used to analyze the granular flows in the charging chute, understand the material behavior and optimize the sinter cooling efficiency.