- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

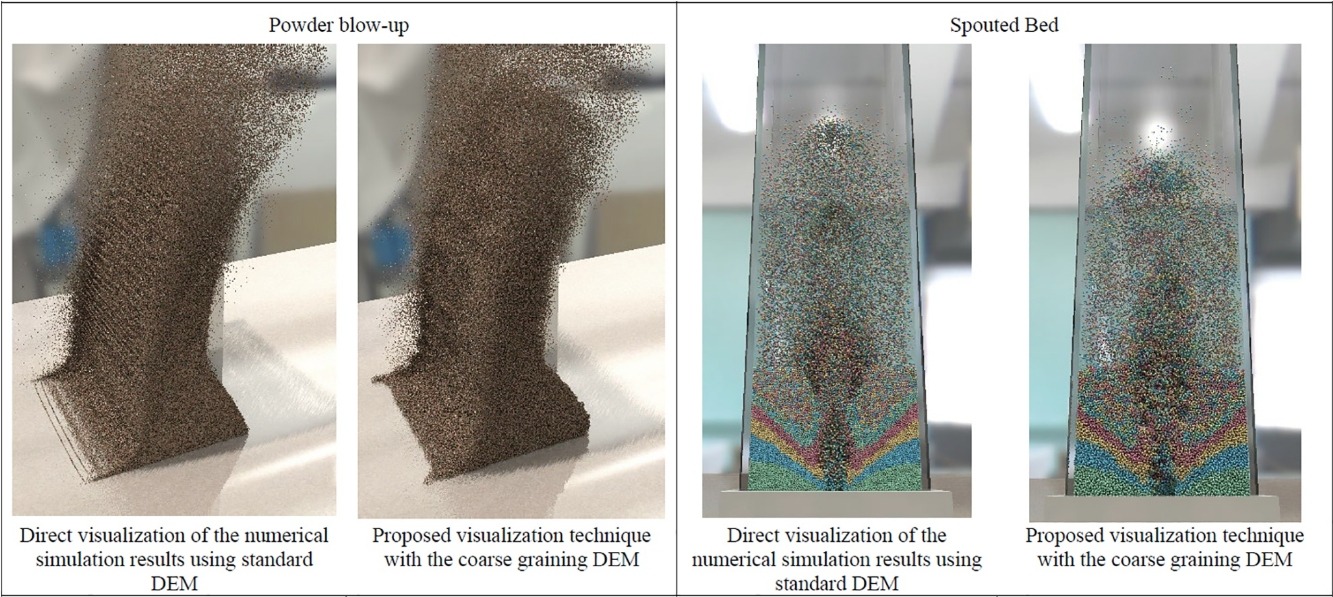

• A realistic visualization method of the coarse graining DEM is proposed.

• Coarse grain particles are decomposed into virtual particles in the proposed method.

• Location of virtual particles is changed by considering the motion and location.

• Calculational efficiency and visualization improvement are shown in this study.

Gas–solid flows are ubiquitous in industrial systems. The coupled model of the discrete element method (DEM) and computational fluid dynamics (CFD) is one of the techniques for the simulation of the gas–solid flows. To enhance the applicability of the DEM-CFD method, the coarse graining DEM has been developed to simulate large-scale powder systems. The coarse graining DEM is a scaling law model and hence can simulate large-scale systems using a smaller number of particles than the actual one. Although the coarse graining DEM enables to effectively simulate large-scale powder systems on a single PC, visualized image is lack of reality due to reduced spatial resolution. Here a novel visualization method is developed to produce realistic images. In the proposed technique, the virtual particles are located by considering the motion and location of the coarse grain particles. To show the adequacy of the proposed method, two types of visualization based on the computational results are made: a blow-up of powder due to injected gas flow and a spouted bed. In these systems, the visualized images are shown to be improved by the proposed visualization technique. The effectiveness of the proposed method is proved by the agreement of the images based on the calculation results between the standard DEM-CFD method and coarse graining DEM.