- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

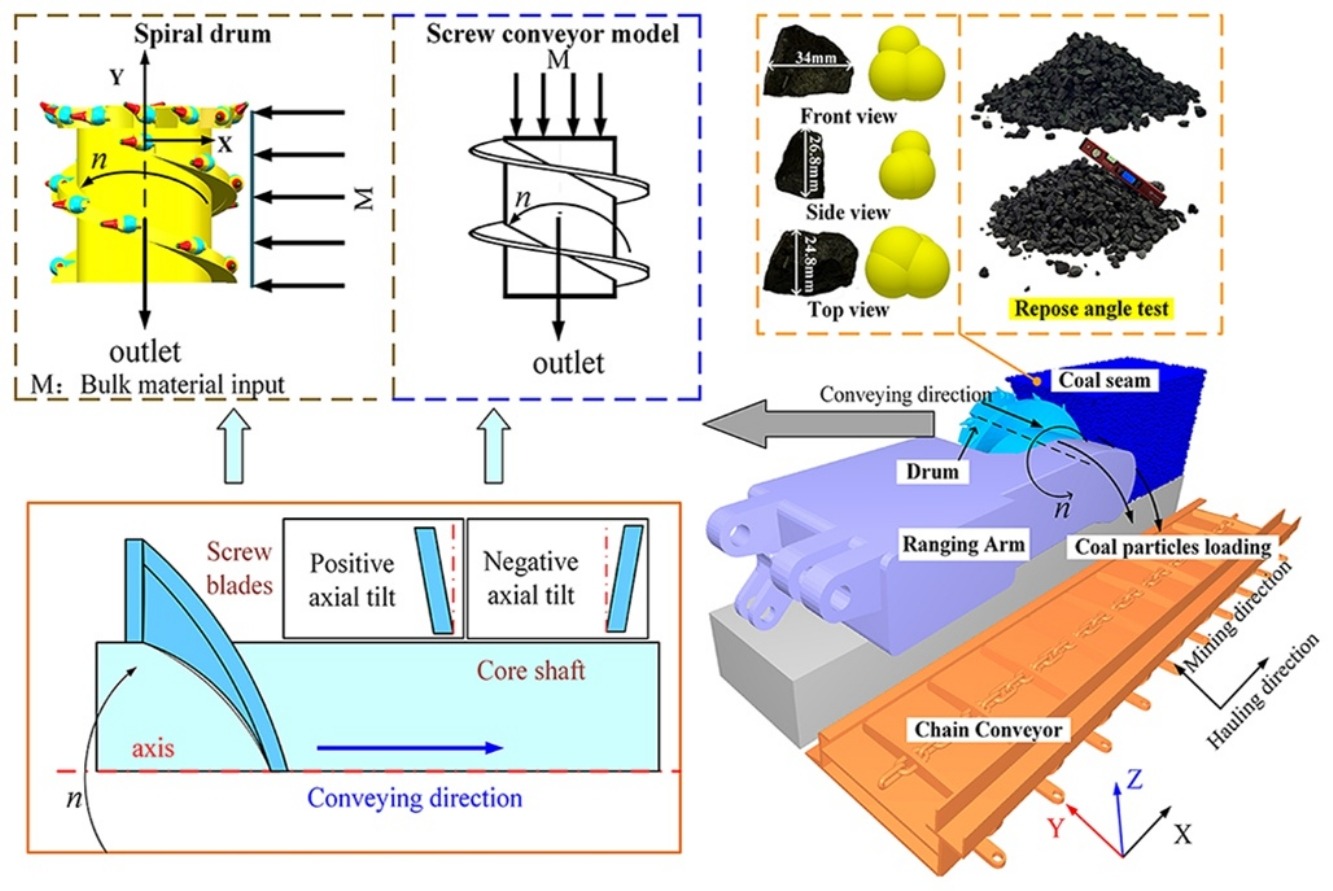

• Effect of blades axial tilt angle on conveying performance was first studied.

• Axial tilt angle had a similar effect on screw conveyor and drum.

• Positive axial tilt angle is beneficial to improve conveying performance.

• Conveying performance of conveyor changes regularly with blade axial tilt angle.

• Axial tilt angle is a priority factor in screw conveyor and drum design.

Screw conveyors are widely employed in industrial fields for conveying bulk materials. The shearer drum which uses the screw conveying principle is responsible for excavation and conveying coal particles onto the chain conveyor. Screw conveyor performance is affected by potential factors, such as the blade axial tilt angle and style, core shaft form and diameter. The effect of blade axial tilt angle on the conveying performance was investigated with the help of DEM. In the case of the screw conveyor, the mass flow rate, and particle axial velocity increased with increasing positive axial tilt angle, and declined with increasing negative axial tilt angle. In the case of the drum, the mass flow rate, particle axial velocity, and loading rate first increased and then decreased with increasing positive axial tilt angle, and decreased with increasing negative axial tilt angle. These results can be considered as a benchmark for screw conveyor and drum structural designs with axial tilt screw blades.