- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

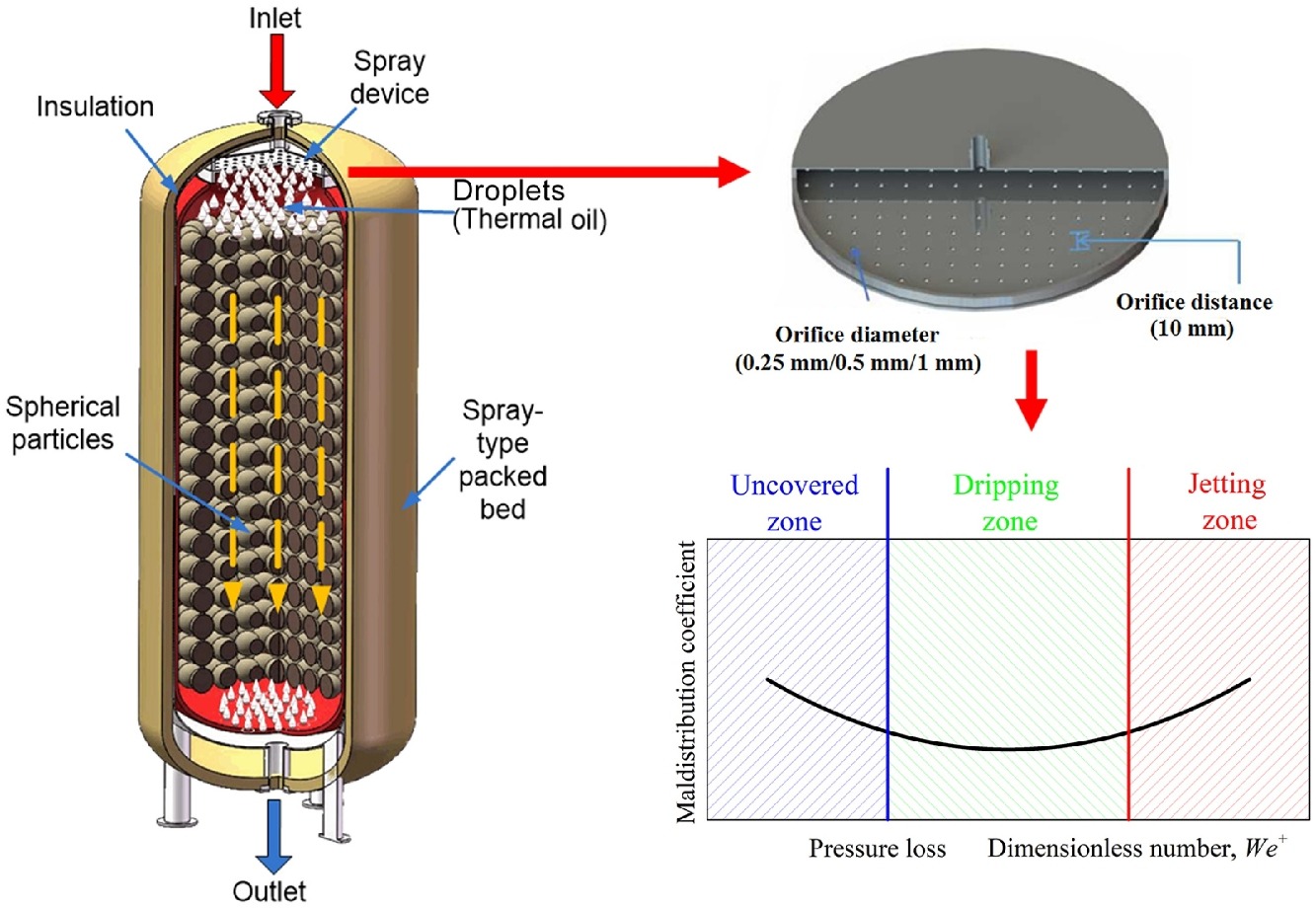

• Perforated plate distributor for spray-type packed bed was proposed.

• Distribution and pressure drop of distributor were measured experimentally.

• Effects of fluid, velocity and orifice diameter on distribution were studied.

• Moderate pressure drop corresponded to more uniform distribution.

• Design criterion for perforated plate distributor was obtained.

As an innovative thermal energy technology, the spray-type packed bed has advantages of high efficiency and low cost. A liquid distributor is the key component for the spray-type packed bed for scattering heat-transfer liquid drops evenly. In this study, the distribution performance and pressure drop of the perforated plate distributors of different orifice diameters were studied experimentally. The experimental results indicate that orifice diameter has a greater effect on the distribution performance compared to flow rate. With an increase in flow rate, the flow pattern through the distributor changes from the uncovered drop to the covered drop and then to the jet flow. The covered drop pattern shows the best performance with a good distribution and a small pressure drop simultaneously, which is the design and optimization principle of the distributor for a spray-type packed bed.