- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

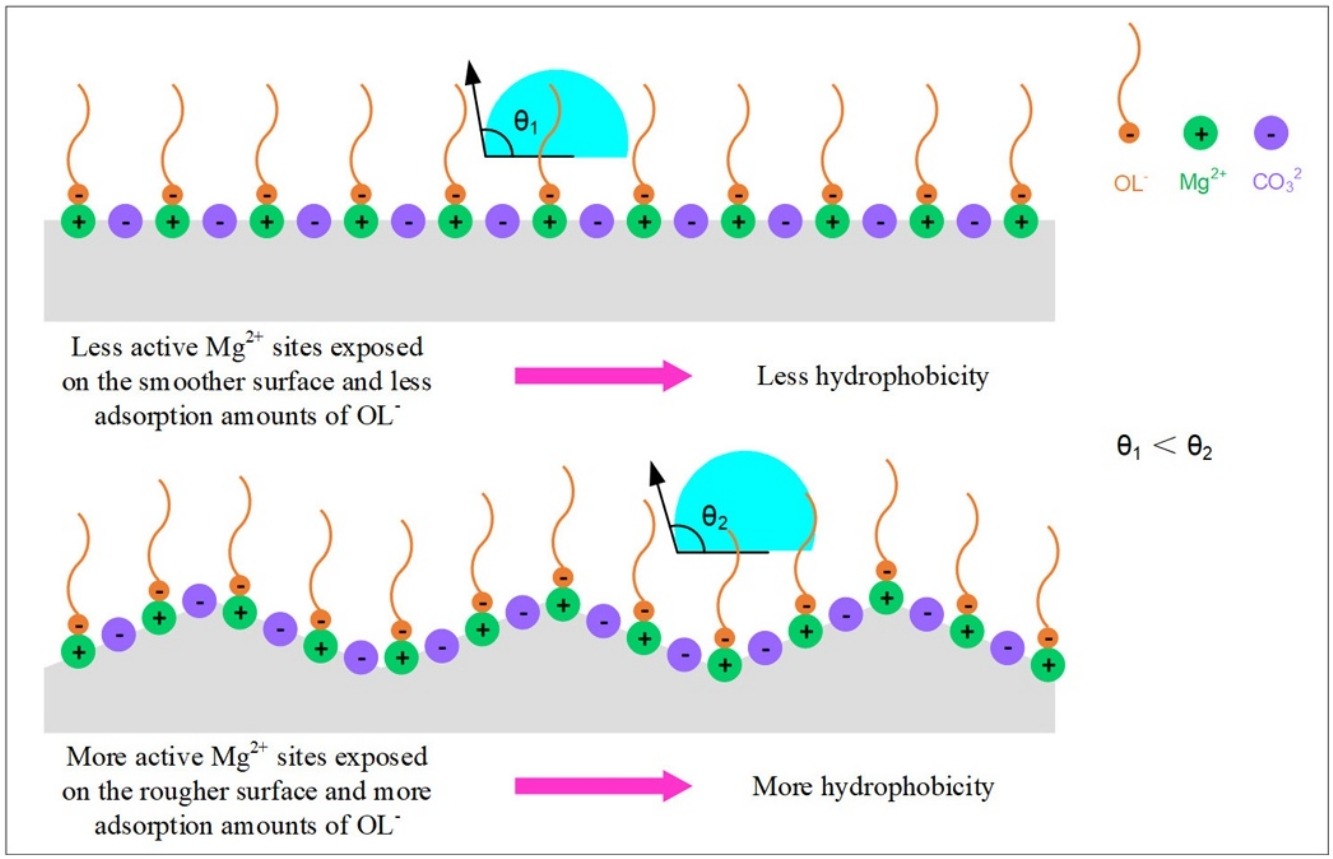

• Exposure degree of surface-active sites influences the floatability of magnesite particles.

• Rougher magnesite particles exposed more active magnesium sites for NaOL adsorption.

• Rougher magnesite particles that adsorb more NaOL exhibited higher hydrophobicity and floatability.

• Rougher surface benefits the efficient recovery of magnesite particles via flotation.

Surface roughness has a significant influence on mineral flotation. The assisting effect of surface roughness on minerals flotation is extensively investigated from its physical properties (e.g., the existing form of asperity and its size), however, the associated effect on mineral flotation based on the differences in surface chemical property caused by surface roughness has been rarely touched. With such a question in mind, in this study, we investigated the flotation recoveries of two batches of magnesite particles with varying degree of surface roughness produced by two different mills, and associated the flotation performances to their surface chemical properties (amount of adsorption sites for the collector) via a series of detections, including Scanning Electron Microscope-Energy Dispersive Spectrometry (SEM-EDS) observations, X-ray photoelectron spectroscopy (XPS) analysis, adsorption capacity tests, and contact angle measurements. Finally, we concluded that rougher magnesite particles could provide more active sites (Mg2+) for a larger capacity of sodium oleate (NaOL), thereby improving the hydrophobicity and floatability.