- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

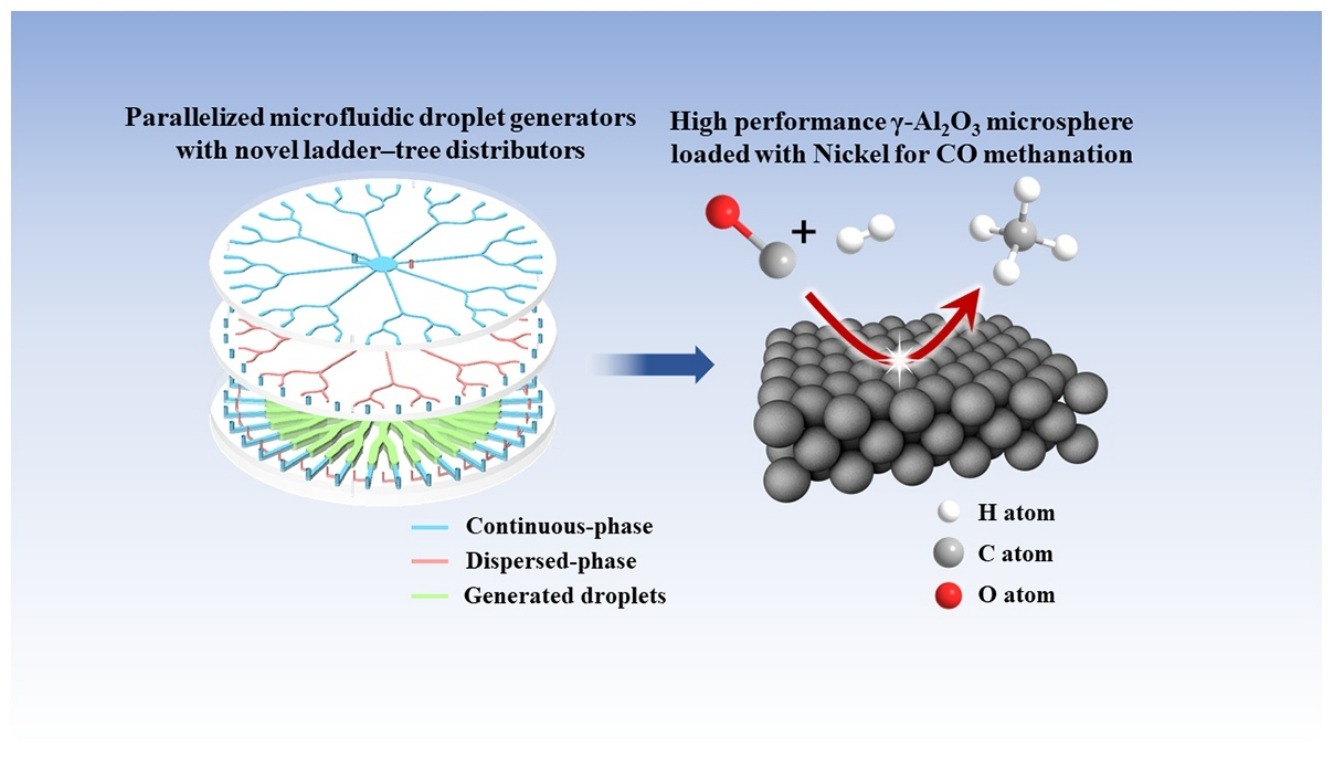

• An improved ladder–tree distributor is proposed and used for microchannel scale-up.

• 2D scale-up effect is investigated using simple water–oil system.

• High-performance γ-Al2O3 microsphere are continuously synthesized.

• Superior catalytic performance of microsphere is demonstrated in methanation.

In this paper, we present a parallelized microfluidic device with improved ladder–tree distributors for the scaled-up production of monodisperse microspheres. Owing to the improved distribution form comprising a ladder distributor in the center and tree distributors around the circumference, the uniformity of the generated droplets for our device was improved by 32.9% and 86.1% compared to those achieved in devices with conventional tree and ladder distributors, respectively, in the final production stage with 32 droplet generators, indicating the potential of our device for further scale-up while maintaining the monodispersity of the generated droplets. The effect of the 2D scale-up of our device was investigated by varying the continuous-phase flow rate and viscosity. Using our device, γ-Al2O3 microspheres with a diameter of 598.1 μm and a CV of 2.58%, as catalyst support for microreactors, were continuously synthesized at high production rate. The nickel-based catalyst prepared from γ-Al2O3 microspheres with large specific surface area and pore volume had an average NiO size of 14 nm, which was 60.9% of that supported on industrial support. The CO methanation conversion of the Ni@Al2O3 microspheres was 1.7 times larger than Ni@Al2O3 industrial support at 140 °C.