- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

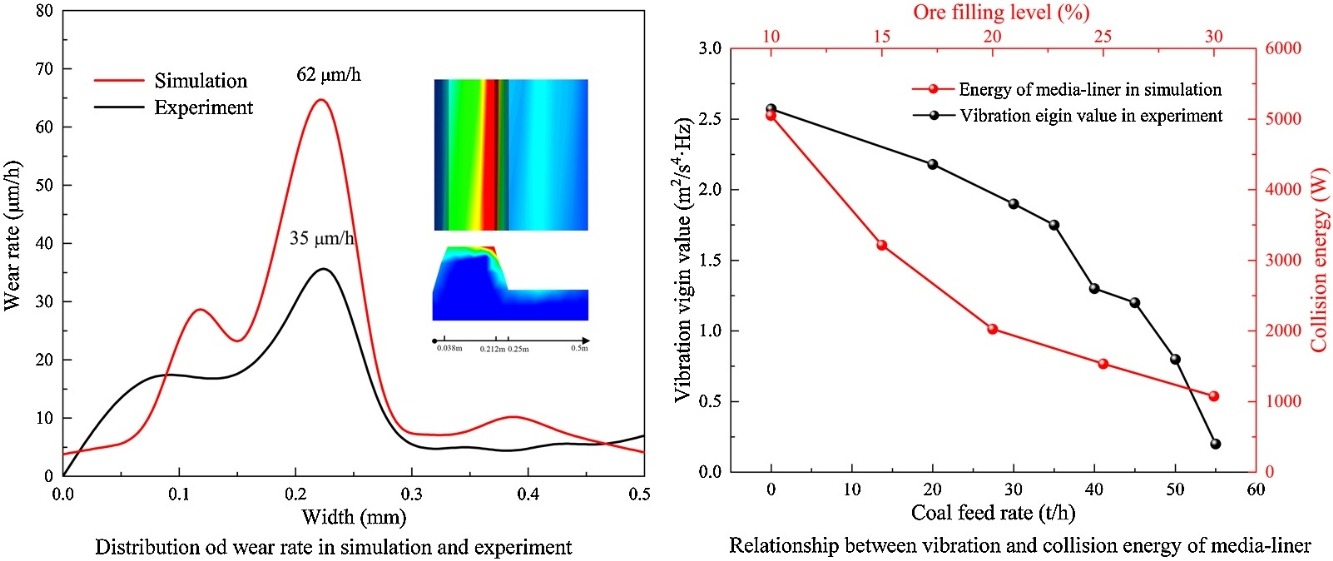

• Influence of filling level on material movement behavior in SAG mill is analyzed.

• Influence of filling level on grinding performance is analyzed with collision energy.

• Influences of filling level on liner and grinding media wear are analyzed.

• The vibration of mill is discussed based on the collision energy on liner.

Semi-autogenous grinding (SAG) mill is widely used in the grinding process of coal and ores because of its strong applicability, large capacity and low consumption of grinding media. Therefore, the research of SAG mill is still of great important practical significance. Among those parameters of the SAG mill, the filling level is very important for it is not only directly related to the processing capacity of the mill, but also affects the operation cost and stability of mill. In this paper, combined with shear impact energy model (SIEM) and discrete element method (DEM), the particle collision energy spectrum was applied to analyze the influence of ore filling level and media filling level on the power draw of the mill, the impact energy on ore, and the wear of liner and media in a slice of an industrial SAG mill. It was found that increasing the ore filling level would increase energy consumption and reduce the energy efficiency and the wear of liner and grinding media. Furthermore, the vibration of mill was explored from the collision energy on liner. The results showed that the low frequency but high energy collision between grinding media and liner was the main reason for liner wear and mill vibration.