- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

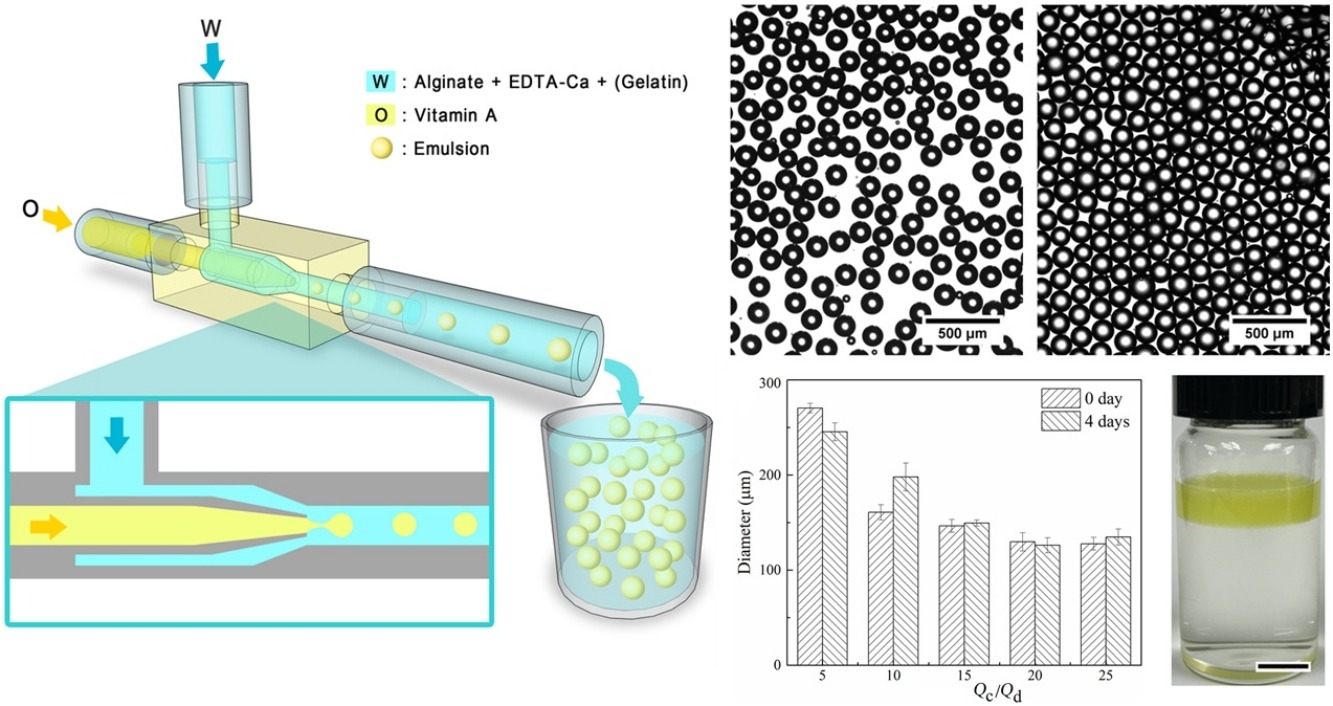

• 3D printed microfluidic device is used to realize encapsulation of vitamin A.

• Alginate and gelatin realize the generation of O/W which contains vitamin A.

• Flow rate ratios have effect on the diameter of droplets.

• O/W emulsion forms microgel particles under the effect of acid.

Microfluidics is characterized by the manipulation of fluids in submillimeter channels and has great application potential in encapsulation. To further extend the application of microfluidics in food industries, a 3D printed microfluidic device is used to encapsulate vitamin A and improve its stability. Two natural macromolecules, sodium alginate and gelatin, are added to water as the continuous phase to generate monodisperse emulsion. Under different flow rate ratios, the diameter of droplets decreases with the increase of continuous flow rate. However, at the same flow rate ratio, varying the dispersed and continuous flow rates does not significantly change the diameter and size distribution of emulsion collected. The prepared O/W (oil/water) single emulsion can form microgel particles and avoid degradation of vitamin A by simulated gastric acid; the encapsulated vitamin A will not be released until particles reach simulated intestinal tract. In the simulated digestion in vitro, no vitamin A is released for 2 h in the acidic environment; under an alkaline or neutral environment such as those in intestinal fluids, vitamin A can be released from the microgel particles within 2.5 h. Using the presented approach, emulsions encapsulating vitamin A have been prepared and can potentially be applied to encapsulate other oil-soluble substances in the food industry.