- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

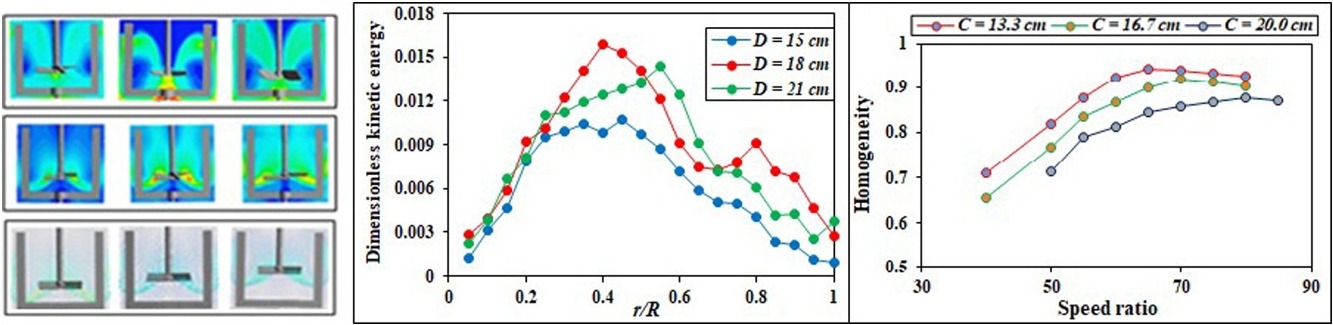

• Dispersion of solids with coaxial mixers was examined via ERT and CFD.

• Loss of energy was minimal for the system with an impeller spacing of 13.3 cm.

• Axial homogeneity enhanced with a decrease in inner impeller clearance.

• Inner stirrer diameter of 18 cm was proper to achieve better suspension quality.

• Use of inner A320 stirrer improved both axial and radial dispersion of solids.

The coaxial mixers enhance the suspension of concentrated slurries in an agitated reactor. In this research work, the complex slurry suspension and dissemination behavior in a coaxial slurry mixing system (comprised of a close clearance anchor rotating with a low speed and an inner axial impeller rotating with a high speed) was analyzed employing ERT (electrical resistance tomography, a non-intrusive flow visualization technique), and computational fluid dynamics (CFD). The numerical models were validated by comparing the axial solid concentration profiles generated using the ERT data and the CFD simulation results. The influences of various important parameters such as the diameter of the inner axial impeller, the inner impeller type, and the inner impeller spacing on the hydrodynamic characteristics of the slurry suspensions in a coaxial mixing vessel were thoroughly analyzed. The radial and axial velocity profiles of solid particles were generated using the validated mathematical models. The assessment of energy loss due to the solid–solid collisions, the particle–fluid frictions, and the particle–vessel wall collisions was conducted. The evaluation of optimum inner impeller clearance and inner impeller diameter is essential to attain a high degree of solids suspension and dissemination in a coaxial slurry mixing system.