- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

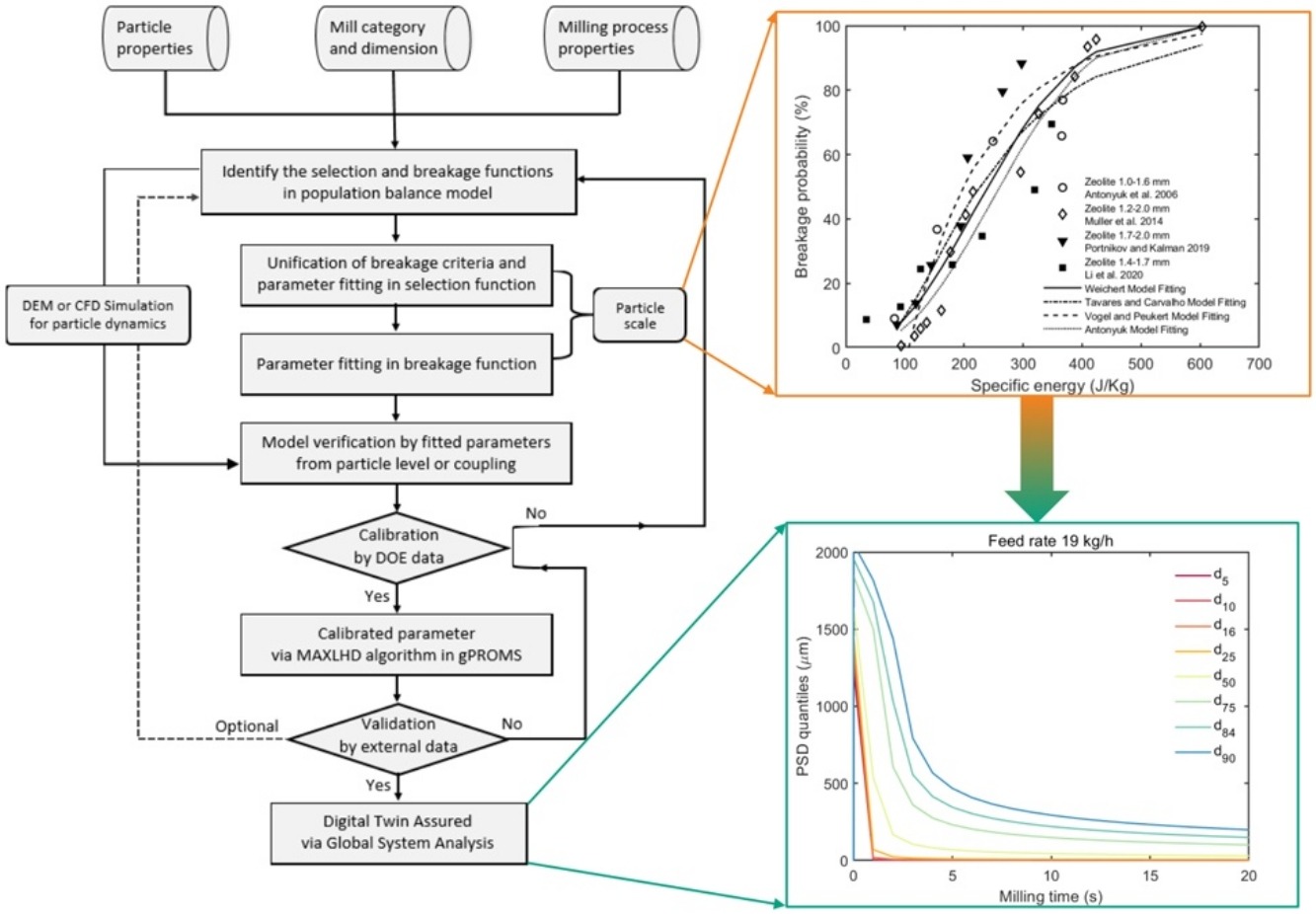

• Impact mode and breakage pattern of particles are summarized.

• Strengths and drawbacks of literature breakage models are scrutinized.

• Particle impact breakage probability is evaluated with unified criteria.

• A novel computational modelling workflow for a milling process is proposed.

• Selection functions are assessed with the value of digital twin highlighted.

This paper presents a thorough study of particle impact breakage in selection function with a unified breakage criterion. The impact mode and breakage pattern for particulate materials are classified based on a significant review of well-established impact testers. It was found that the lack of a unified breakage criterion to determine the breakage probability disables a direct comparison of particle breakage propensity from different impact loading testers. The literature breakage models to describe the breakage probability are reviewed where the advantage and drawback of these models are scrutinized. The sourced literature breakage models are compared with the zeolite breakage datasets in a unified breakage criterion to evaluate the model performance. A novel computational modelling workflow for a milling process is proposed to provide a guidance in implementing the digital twin in milling process prediction. The breakage probability models, i.e. the selection functions are comprehensively assessed in population balance model to examine the model serviceability. The model simplicity and fidelity in the model assessment are specifically discussed and the value of digital twin in substantially reducing the experimental trials is highlighted.