- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

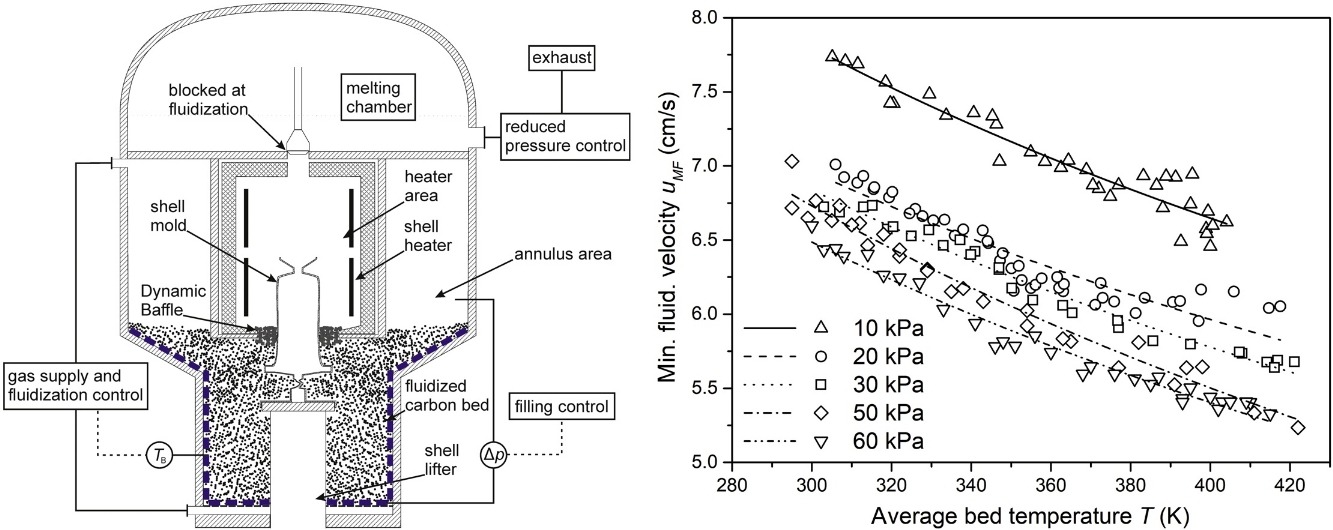

• Carbon particles for application in fluidized bed casting device were studied.

• Carbon glass beads showed Geldart B fluidization behavior at reduced pressures.

• Fluidization velocity decreased with increased temperatures.

• Stable fluidization at absolute pressures reaching from 10 to 100 kPa was observed.

Fluidized Carbon Bed Cooling (FCBC) is an innovative investment casting process for directional solidification of superalloy components. It takes advantage of a fluidized bed with a base of small glassy carbon beads for cooling and other low-density particles that form an insulating layer by floating to the bed surface. This so-called “Dynamic Baffle” protects the fluidized bed from the direct heat input from the high-temperature heating zone and provides the basis for an improved bed microstructure. The prerequisites for a stable casting process are stable fluidization conditions where neither collapse of the bed nor particle blow out at excessive bubble formation occur.

This work aimed to investigate the fluidization behavior of spherical carbon bed material in argon and air at temperatures between 20 to 350 °C. Systematic studies at reduced pressures using the FCBC prototype device were performed to understand the stable fluidization conditions at all stages of the investment casting process. The particle shape factor and size distribution characterization and the measurement of the powder’s minimum fluidization velocity and bed voidage show that this material can be fully utilized as a cooling and buoyancy medium during the FCBC process.