- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

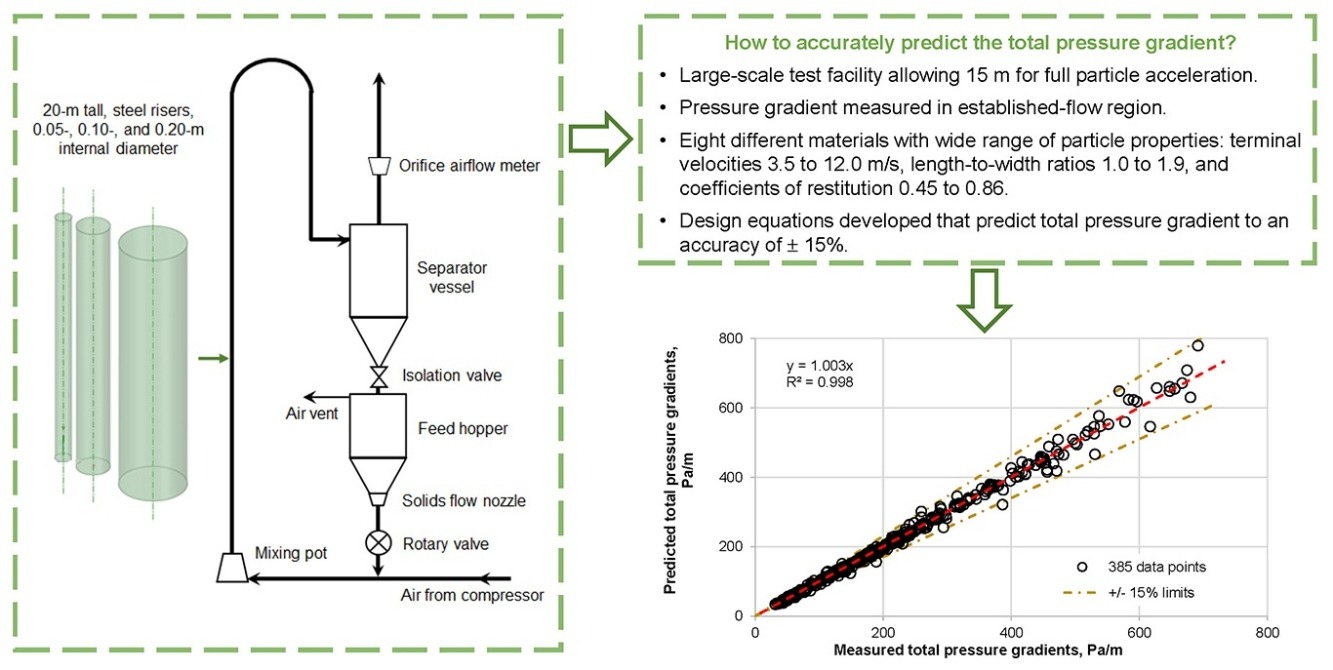

• An evaluation of vertical dilute-phase pneumatic conveying data is reported.

• Based on rigorous data analysis the equation of motion is redefined.

• Correct basis for collecting and reporting data is established.

• Pressure drops for range of materials and riser diameters are accurately predicted.

• Pressure drop minima and associated gas velocities are predicted by same procedure.

An analysis has been completed for a comprehensive set of vertical, dilute-phase pneumatic conveying pressure drop data from an investigation by Flatow. The data were collected in the established flow region for eight different materials conveyed in 0.05-, 0.10-, 0.20-m internal diameter, 20-m tall steel risers. Particle velocities derived from the pressure drop data were used to develop an equation of motion that includes terms for pipe diameter, terminal velocity, coefficient of restitution, and particle shape. The best data fit was achieved using the actual gas density and the actual gas velocity adjusted for voidage. Adjusting the terminal velocity for voidage, an approach recommended by many investigators, did not improve the fit for reasons identified by the present research.

Using the equation of motion, particle velocities were predicted and used to calculate total pressure drops that are within ±15% of the measured values. The calculated values also produce the characteristic trough-shaped total pressure drop curves allowing the minimum pressure drop gas velocity to be determined without recourse to a separate correlation. A comparison with other studies using shorter risers indicates that data from these studies likely include acceleration effects. A separate study will investigate this observation further.