- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

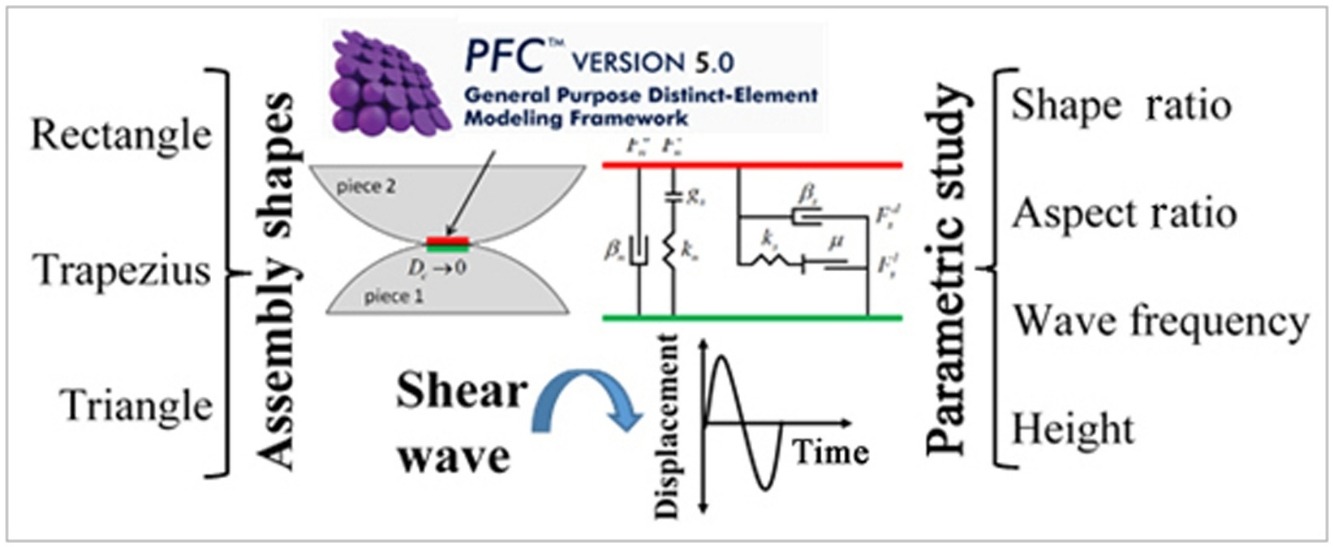

• Shear wave propagation was simulated using discrete element method (DEM).

• Assembly shape effect on the amplification factor was studied.

• Various assembly shapes caused the amplification occur at different locations.

• Amplification factor of triangular assembly was more than trapezoidal one.

• Rectangular assemblies with an aspect ratio of >3.25 showed amplification.

The discrete element method (DEM) is a capable tool used to simulate shear wave propagation in granular assemblies for many years. Researchers have studied assembly shapes such as rectangles (in 2D simulations) or cylinders and cubes (in 3D simulations). This paper aimed to qualify the effect of assembly shape on the shear wave propagation and maximum amplification in the vertical plane (horizontal and vertical directions) caused by this propagation. To this end, shear wave propagations in different assembly shapes such as rectangle, trapezium, and triangle with rigid boundary conditions were simulated. A sine wave pulse was applied with a point source by moving a particle as the transmitter particle. To evaluate the shear wave velocity of the assemblies, the transmitter and receiver particles were simulated. All the simulations were performed with 2D DEM which is a useful tool to determine the amount and location of the maximum amplification factor of the assembly in both horizontal and vertical directions. An advantage of this study was assessing the effect of parameters such as input wave frequency, assembly height, shape, and aspect ratios on the amplification of the input waves.