- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

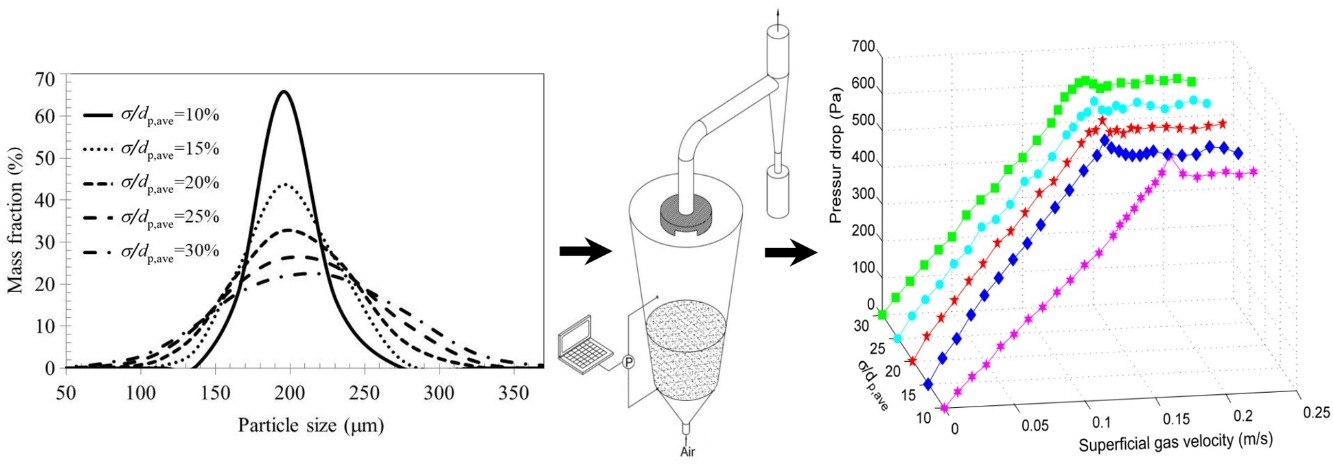

• Determining minimum fluidization velocity (Umf) for particles with Gaussian size distribution.

• Evaluating the effects of Gaussian distribution width on Umf.

• Developing an empirical model including the effect of distribution width for Umf.

• Comparing experimental data with proposed model and other exiting models.

This paper investigated the effect of Gaussian distribution width, average particle diameter, particle loading, and the tapered angle on minimum fluidization velocity (Umf) by conducting extensive experiments in tapered fluidized beds. Three powders with Gaussian size distribution and different distribution widths were used in the experiments. An increase in Umf with increasing the average particle diameter, particle loading, and the tapered angle was observed. There was also a nonmonotonic behavior of Umf as the Gaussian distribution width increased. An empirical correlation including dimensionless groups for predicting Umf in tapered beds was developed in which the effect of distribution width was considered. The proposed correlation predictions were in good agreement with the experimental data, with a maximum deviation of 16.5% and average and standard deviations of, respectively, 6.4% and 7.4%. The proposed correlation was also compared with three earlier models, and their accuracy was discussed.