- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

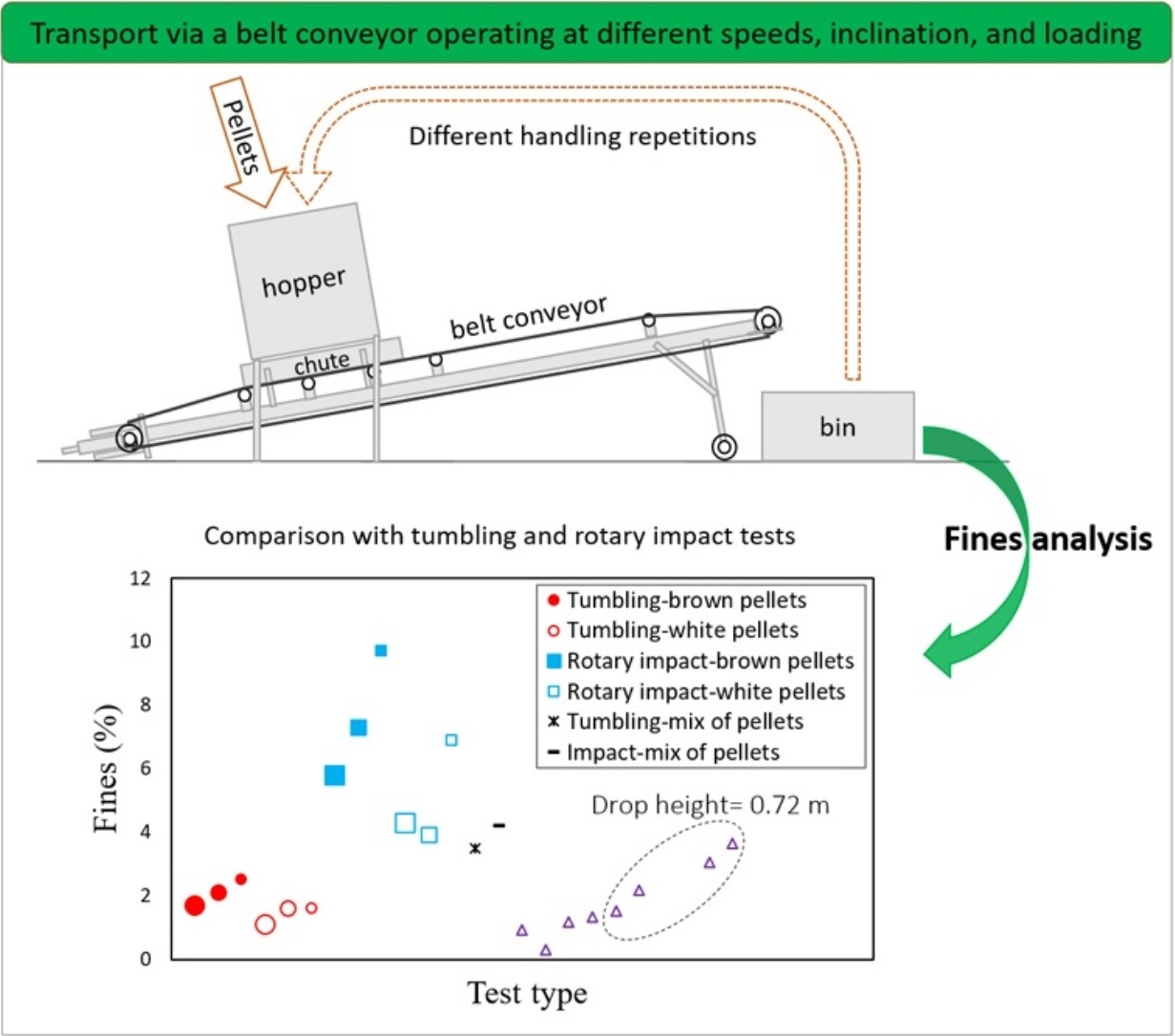

• Fines generation during transport was studied via analysis of variance.

• Number of handling steps and belt inclination were of high significance.

• Fines generation results were compared with those of the benchmark tests.

• Tumbling box method can predict fines generation with high fidelity.

This work investigates the proportion of generated fines in a pilot-scale experiment using a belt conveyor and commercial fuel pellets. For this, a belt conveyor with a length of 3.1 m was used and operated at varying conditions: speeds, percentages of material loading on the belt, two combinations of the inclination angle of the belt and the falling height, and a different number of handling steps. We considered a design of experiments approach based on response surface methodology to investigate the effect of different conditions on the potential of fines generation. Moreover, a comparison between the results of the belt conveyor and three common benchmark experimental approaches (tumbling box, rotary impact tester, and mechanical compression test) was made. Results show that the number of handling steps and the combined effect of drop height and inclination angle directly affected the fines generation. However, the tested belt speed range and the level of loading were of lower significance. A polynomial quadratic model was derived based on the regression analysis and showed a high accuracy to predict the proportion of fines. Moreover, the tumbling box method showed good potential to predict the proportion of fines in a belt conveyor when transported several times.