- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

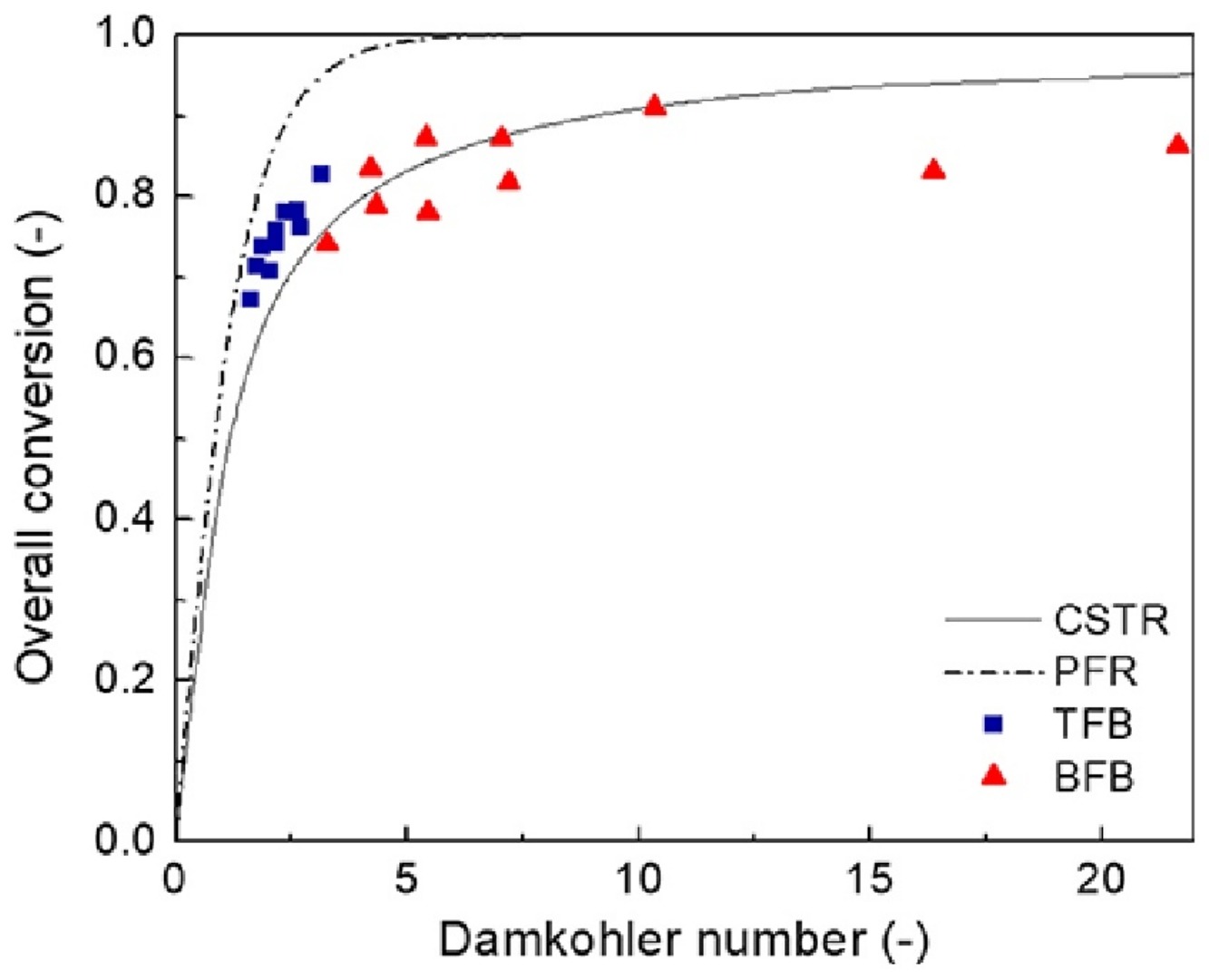

• Reactor performance of low-velocity fluidized beds with superficial gas velocity 0.1–1.2 m/s.

• TFB demonstrates better reactor performance than BFB.

• TFB is more similar to that of a plug flow reactor.

• TFB has higher gas–solids contact efficiency than BFB.

• High ozone conversion takes place in entrance region near the gas distributor.

Reactor performance of bubbling fluidized bed (BFB) and turbulent fluidized bed (TFB) was carefully examined and systematically compared using catalytic ozone decomposition as a model reaction, based on a complete mapping of local flow structures and spatial distributions of ozone conversion and solids holdup. TFB clearly has a higher conversion and shows better reactor performance than BFB as a result of the vigorously turbulent flow and the relatively homogeneous gas–solids mixing in TEB. Besides, the intensive interaction between gas and solids in TFB leads to greater gas–solids contact efficiency of TFB over that of BFB. Due to gas bypassing and backmixing caused by bubbling behaviours and two-phase structure, BFB deviates significantly from a plug flow reactor and sometimes from a continuously stirred tank reactor. The flow structures essentially dictate the reactor performance in the low-velocity fluidized beds.