- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Three-dimensional fluidized bed with pulsating flow was modeled successfully.

• Pulsating flow provided higher conversion and yield than non-pulsating flow.

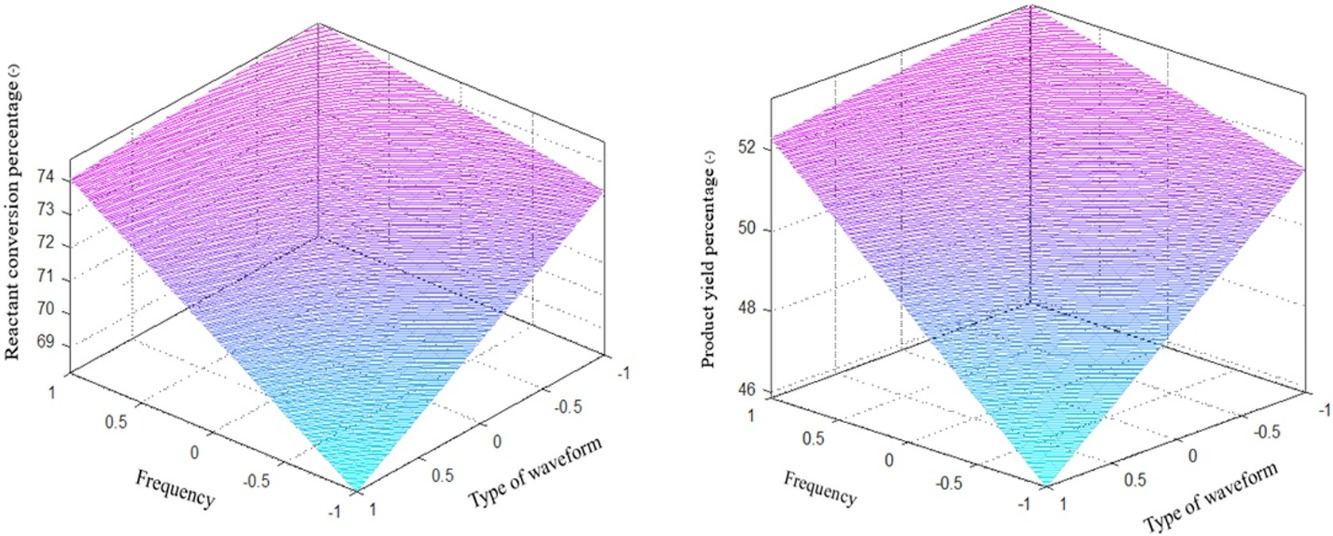

• Frequency and types of the waveform were important pulsating operating parameters.

• Sine-shaped waveform gave uniformly axial solid distribution than squared-shaped.

• Regression models to optimize reaction conversion and yield were established.

The three-dimensional computational fluid dynamics (3D-CFD) of a pulsating flow applied to the fluid catalytic cracking (FCC) reaction was investigated in the riser of a circulating fluidized bed reactor. The kinetic parameters of the FCC and coke burning reactions for predicting the reactant conversion and product yield percentages were applied. To increase the reactant conversion level and product yield, the effect of the pulsating flow operating parameters was considered using a 2k statistical experimental design with four factors (amplitude, frequency, types of the waveform, and amplitude ratio). The 3D-CFD simulation was successfully validated from the experimental literature data. The frequency and type of the waveform were found to be the significant operating parameters. The expression of the fitted regression model and response surface contour were derived and revealed that the pulsating flow provides a higher reactant conversion level and product yield percentages compared to a non-pulsating or steady flow.