- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

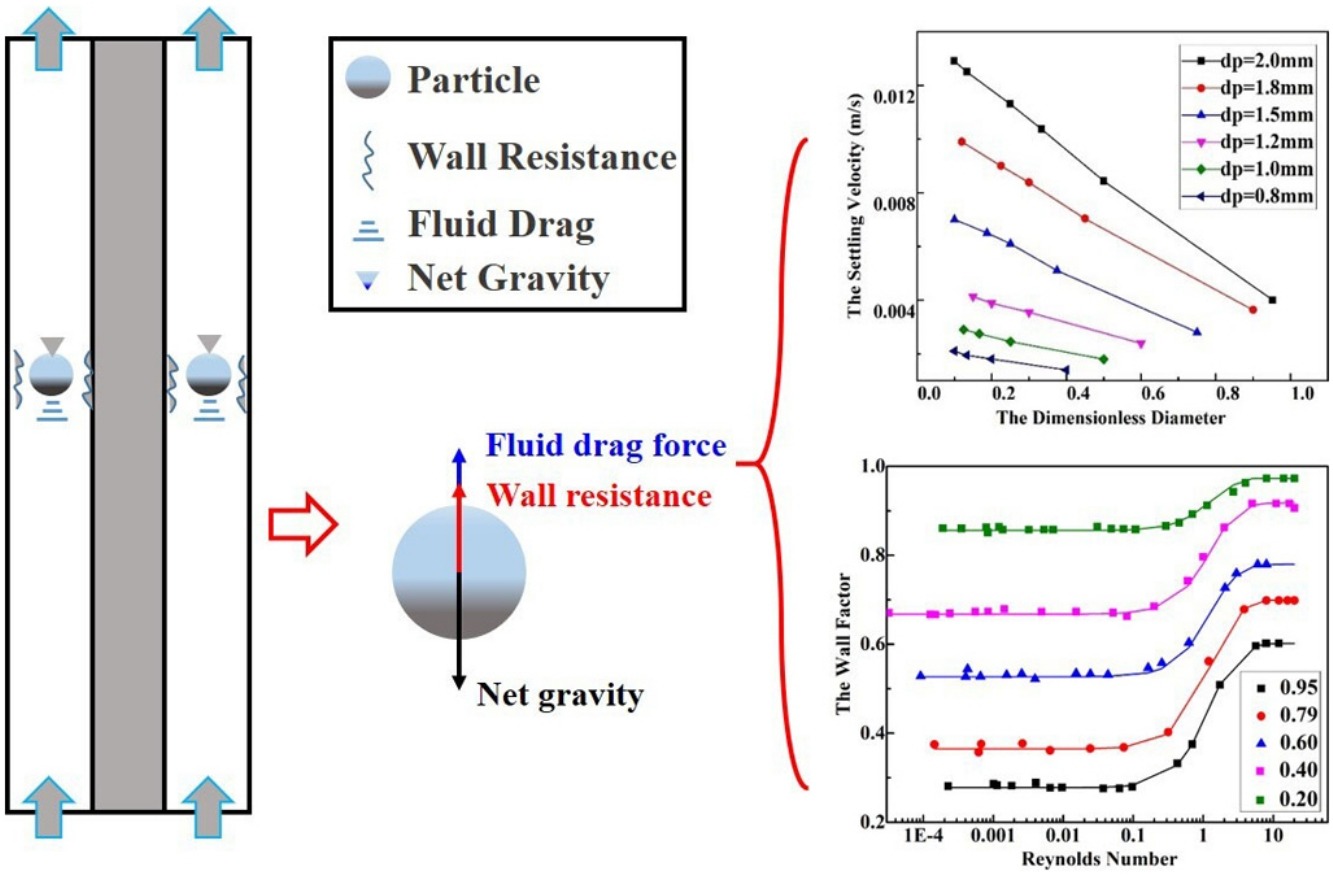

• Settling behavior of spheres in vertical annulus is revealed.

• Relationship between wall factor and rheological behavior of power-law fluids is revealed.

• Wall factor model of annulus filled with power-law fluids is established.

• An explicit model of the settling velocity for sphere in the annulus is established.

• Effects of particle shape and wall roughness on settling behavior need more attention.

Coiled tubing (CT) drilling technology offers significant advantages in terms of cost and efficiency for exploitations of unconventional oil and gas resources. However, the development of CT drilling technology is restricted by cuttings accumulation in the wellbore due to non-rotation of the drill string and limited circulating capacity. Cuttings cleaning becomes more difficult with the wall resistance of pipe-wellbore annulus on the cutting transport. Accurate description of particle transport process in the pipe-wellbore annulus is, therefore, important for improving the wellbore cleanliness. In this study, high-speed camera is used to record and analyze the settling process of particles in the transparent annulus filled with power-law fluids. A total of 540 tests were carried out, involving dimensionless diameters of 0.10–0.95 and particle Reynolds Numbers of 0.01–12.97, revealing the effect of the dimensionless diameter and particle Reynolds number on the annulus wall effect, and the wall factor model with an average relative error of 2.75% was established. In addition, a dimensionless parameter, Archimedes number, independent of the settling velocity, was introduced to establish an explicit model of the settling velocity of spherical particles in the vertical annulus, with the average relative error of 7.89%. Finally, a calculation example was provided to show how to use the explicit model of settling velocity in annulus. The results of this study are expected to provide guidance for field engineers to improve the wellbore cleanliness of coiled tubing drilling.