- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

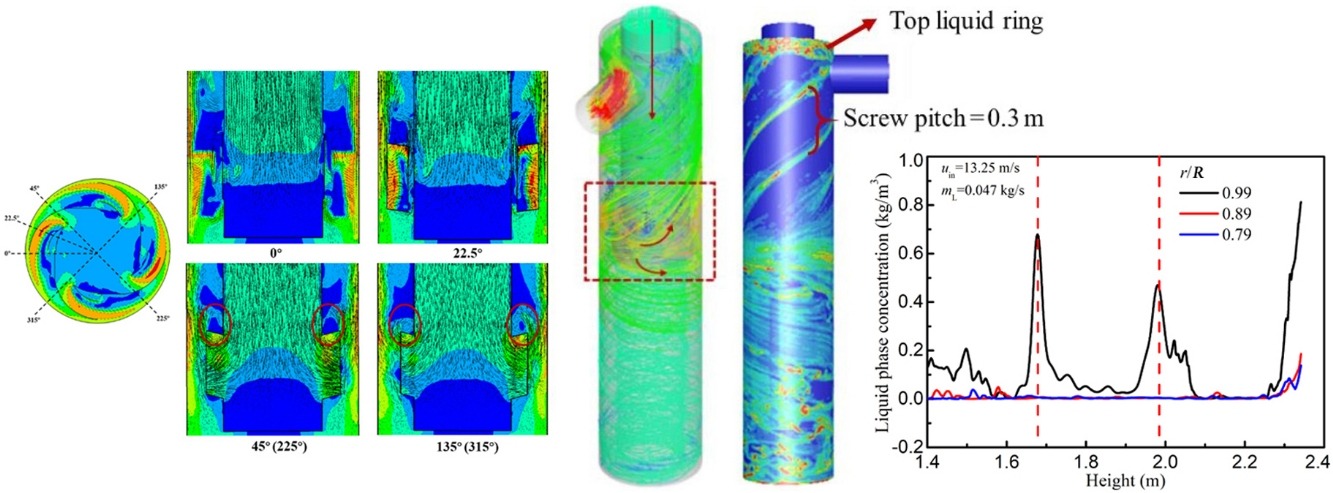

• Separation efficiency is influenced by flow field and liquid phase concentration.

• The transverse vortex entrains the small droplets into the upper annulus zone.

• Higher liquid phase concentration in the top liquid ring reduces the efficiency.

• The annular zone height affects the efficiency but does not affect the pressure drop.

• The annular zone height of 940 mm is the most economical.

Fischer–Tropsch (F–T) synthesis is an important route to achieve the clean fuel production. The performance of gas–liquid separation equipment involving in the progressive condensation and separation of light and heavy hydrocarbons in the oil-gas products has become a bottleneck restricting the smooth operation of the F–T process. In order to remove the bottleneck, a gas–liquid vortex separator with simple structure, low pressure drop and big separation capacity was designed to achieve the efficient separation between gas and droplets for a long period. The RSM (Reynolds Stress Model) and DPM (Discrete Phase Method) are employed to simulate the flow characteristics and liquid distribution in the separator. The results show that the separation efficiency is influenced by the flow field and liquid phase concentration in the annular zone. The transverse vortex at the top of spiral arm entrains the droplets with small diameter into the upper annular zone. The entrained droplets rotate upward at an angle of about 37.4°. The screw pitch between neighbor liquid threads is about 0.3 m. There is a top liquid ring in the top of annular zone, where the higher is the liquid phase concentration, the lower is the separation efficiency. It is found that by changing the operating condition and the annular zone height the vortex can be strengthened but not enlarged by the inlet velocity. The screw pitch is not affected by both inlet velocity and annular zone height. The liquid phase concentration in the top liquid ring decreases with both the increases of inlet velocity and annular zone height. The total pressure drop is almost not affected by the annular zone height but is obviously affected by the inlet velocity. When the height of annular zone is more than 940 mm, the separation efficiency is not changed. Therefore, the annular zone height of 940 mm is thought to be the most economical design.