- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A horizontal high-shear granulator was used for iron ore fine granulation.

• Granulation performance at different shear conditions was analyzed.

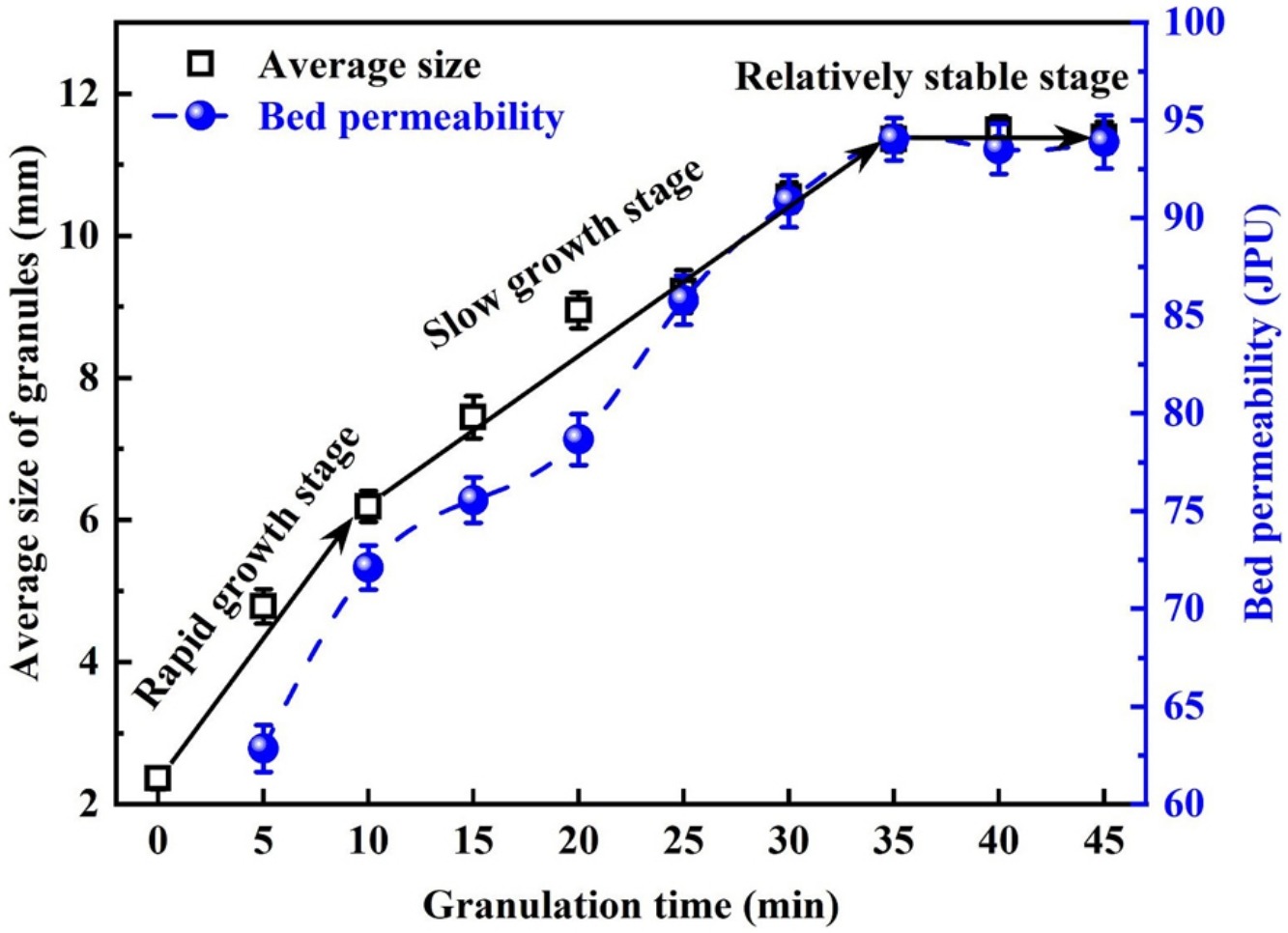

• Growth of granules can be divided into three stages in granulation process.

High-shear granulation is widely used in many particulate industries for its good capability to improve the size, strength and composition uniformity of powder substances. This work conducted an experimental study to investigate the granulation behavior of iron ore fine in a horizontal high-shear granulator, such as granules size distribution, granules growth rate, and permeability of the granules bed. The results show that the granule size and permeability of packed granules bed increase gradually with increasing the granulation time, and the growth of granules can be divided into three stages: the rapid growth stage, the slow growth stage and the relatively stable stage. Both the higher rotational speed and larger number of impellers increase the kinetic energy and collision frequency of the particles, which causes the increase of average granule size, growth rate and permeability of granules packed bed. On the other hand, the shear damage effect of the impellers on the granules is also enhanced with the increase of rotational speed and impeller number, resulting in significant granule size segregation.