- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

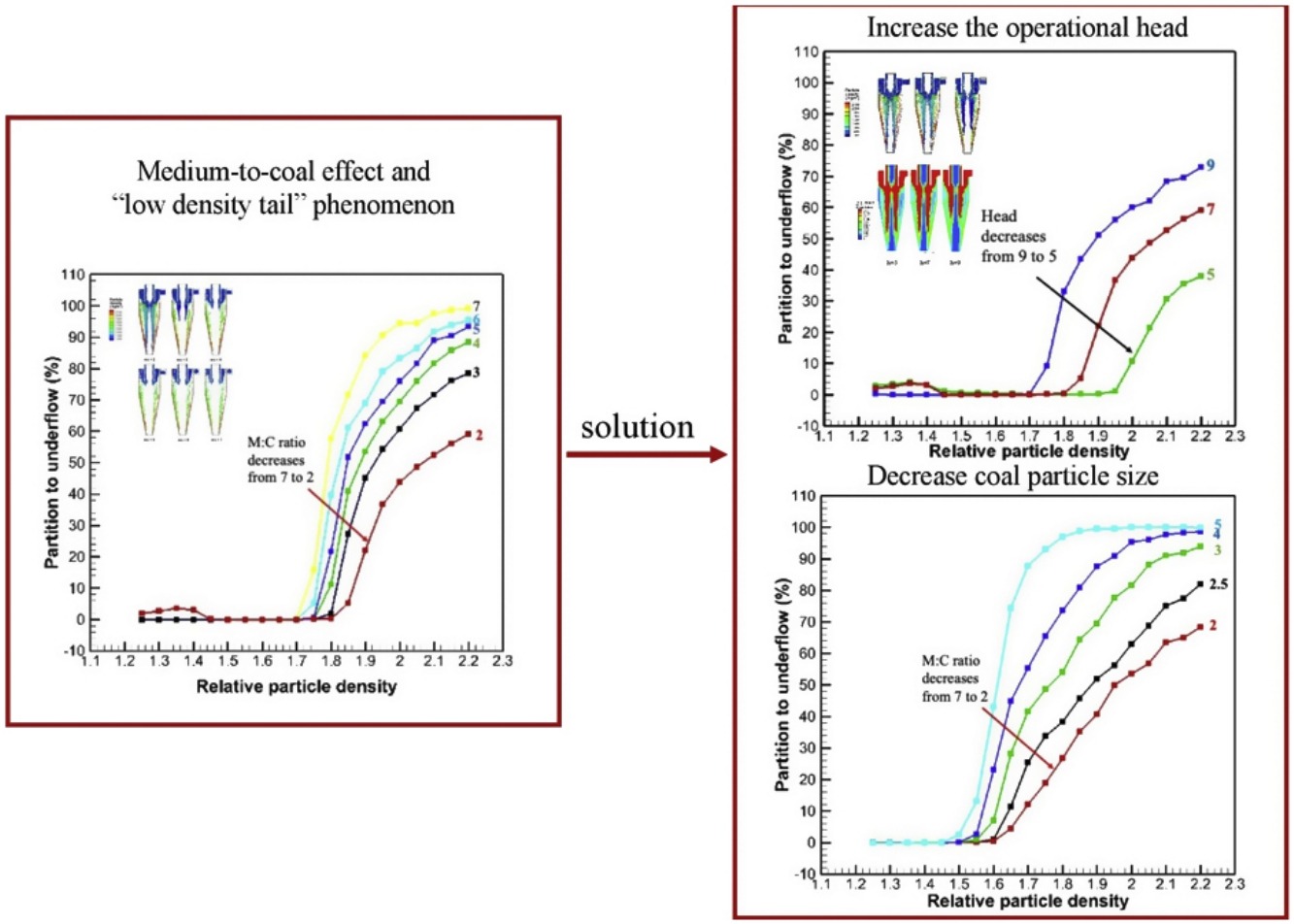

• Medium-to-coal (M:C) ratio effect of dense medium cyclone (DMC) is studied in conditions close to practice.

• M:C ratio affects DMC performance significantly.

• Specific effect of M:C ratio depends on coal size/density distributions.

• “Low-density coal tail” phenomenon is reproduced.

• Methods are proposed to mitigate “low-density coal tail” phenomenon.

Dense medium cyclone (DMC) is the working horse in coal industry. In practice, it is usually operated under constant pressure and the operational conditions (mainly medium-to-coal (M:C) ratio and operational pressure) need to be adjusted according to coal washability data (mainly coal particle size and density distributions). Nonetheless, until now it is still not well understood how the M:C ratio would affect the performance of DMCs especially under the practical conditions. In this work, the effect of M:C ratio is for the first time numerically studied under conditions similar to plant operation by using both traditional and coarse-grained (CG) combined approach of computational fluid dynamics (CFD) and discrete element method (DEM), called as traditional CFD-DEM and CG CFD-DEM, in which the flow of coal particles is modelled by DEM or CG DEM which applies Newton’s laws of motion to individual particles and that of medium flow by the conventional CFD which solves the local-averaged Navier-Stokes equations, allowing consideration of particle–fluid mutual interaction and particle–particle collisions. Moreover, impulse and momentum connection law is used to achieve energy conservation between traditional CFD-DEM and CG CFD-DEM. It is found that under constant pressure, the M:C ratio affects DMC performance significantly. The specific effect depends on coal washability or coal type. Under extremely low M:C ratio, the phenomenon that high-quality coal product is misplaced to reject is successfully reproduced, which has been observed in plants in Australian coal industry and called as “low-density tail”. Moreover, strategies are proposed to mitigate the “low-density tail” phenomenon based on the model.