- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

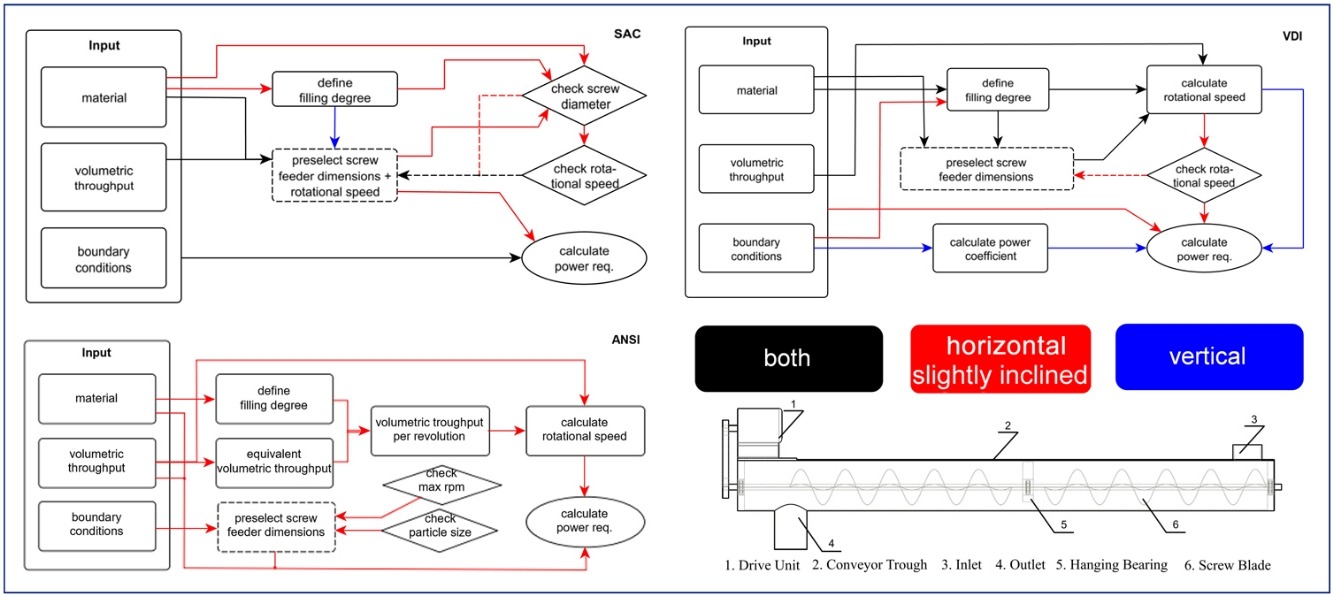

• First comparative study on standards of screw conveyor from China, Germany and USA.

• Case studies on representative materials are conducted to obtain quantitative results.

• Influences of experimental design parameters on power consumption are unveiled.

• Concluding comments are made in view of global integration of manufacturing of screw conveyor.

Screw conveyors, widely used devices for transporting bulk materials, play an irreplaceable role in the modern industrial system. Despite of their traditional advantages, designers of screw conveyors still heavily rely on their own country’s experiments and standards, which are closely related to empirical data. Therefore, the same conveying task often results in different designs. This work aims to compare the design standards of screw conveyors in China, Germany and the USA. Based on related standards acquired from renowned associations in the three countries, the similarities and particularities of these design guidances are compared. With preforming the geometrical and operational designs for horizontal, slightly inclined and vertical conveyance of three representative bulk solids (barley, lignite, sand), the advantages and disadvantages of these semi-empirical designs are comprehensively presented. Furthermore, the potential influence of empirical coefficients, which are not explicitly documented, are extensively discussed. By analysing all outcomes, the compatibility and applicability of each standard are qualitatively assessed.