- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

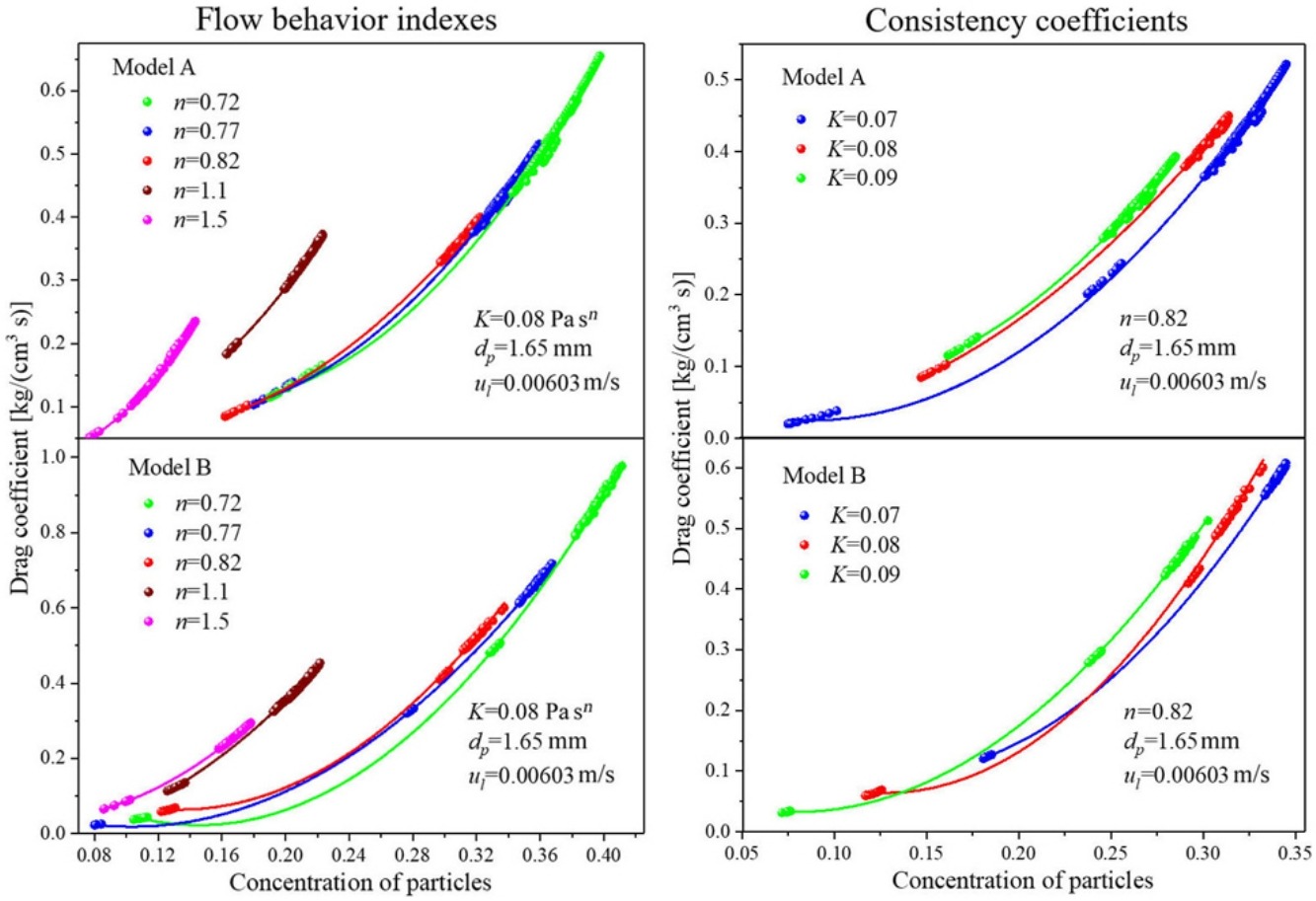

• Based on rheology and pressure drop, power-law liquid–solid drag models are derived.

• Power-law liquid–solid drag models have a better agreement with experiments.

• Classic core-annulus flow structure of particles is captured.

• Increasing consistency coefficient and flow behavior index, drag coefficient decreases.

In this study, a Eulerian-Eulerian two-fluid model combined with the kinetic theory of granular flow is adopted to simulate power-law fluid–solid two-phase flow in the fluidized bed. Two new power-law liquid–solid drag models are proposed based on the rheological equation of power-law fluid and pressure drop. One called model A is a modified drag model considering tortuosity of flow channel and ratio of the throat to pore, and the other called model B is a blending drag model combining drag coefficients of high and low particle concentrations. Predictions are compared with experimental data measured by Lali et al., where the computed porosities from model B are closer to the measured data than other models. Furthermore, the predicted pressure drop rises as liquid velocity increases, while it decreases with the increase of particle size. Simulation results indicate that the increases of consistency coefficient and flow behavior index lead to the decrease of drag coefficient, and particle concentration, granular temperature, granular pressure, and granular viscosity go down accordingly.