- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

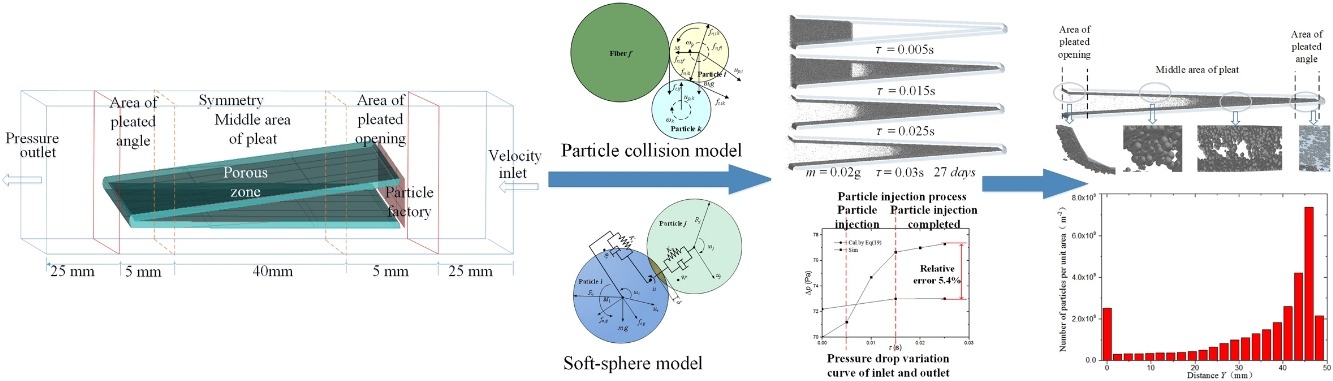

• CFD–DEM coupling method was applied to macroscopic simulation of pleated air filter media.

• Pleated air filter media was simplified as porous media (porous zone).

• Deposition process of particles in different regions was observed.

• Influence of particles deposition on air distribution and pressure drop was analyzed

In this study, the three-dimensional physical model of pleated air filtration media was simplified to porous media model, and the calculation parameters of porous media were obtained based on experimental data. The model of V-shaped pleated air filter media is constructed, the height of the media pleat is 50 mm and the pleat thickness is 4 mm, the pleat angle is 3.7°. The Hertz-Mindlin contact model was modified by Johnson Kendall Roberts (JKR) adhesion contact model. The deposition process of particles in media was simulated based on computational fluid dynamics (CFD) theory and discrete element method (DEM). Results show that the CFD–DEM coupling method can be effectively applied to the macro research of pleated air filter media. The particles will form dust layer and dendrite structure on the fiber surface, and the dust layer will affect the subsequent air flow organization, and the dendrite structure will eventually form a “particle wall”. The formation of the “particle wall” will prevent the particles from moving further in the fluid domain, which makes area of pleated angle become the “low efficiency” part about the particle deposition. Compared with area of pleated angle, the particles are concentrated in the opening area and the middle area of the pleated to agglomerate and deposit.