- Volumes 84-95 (2024)

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Immediate release of tadalafil due to amorphization and solubilization in Soluplus.

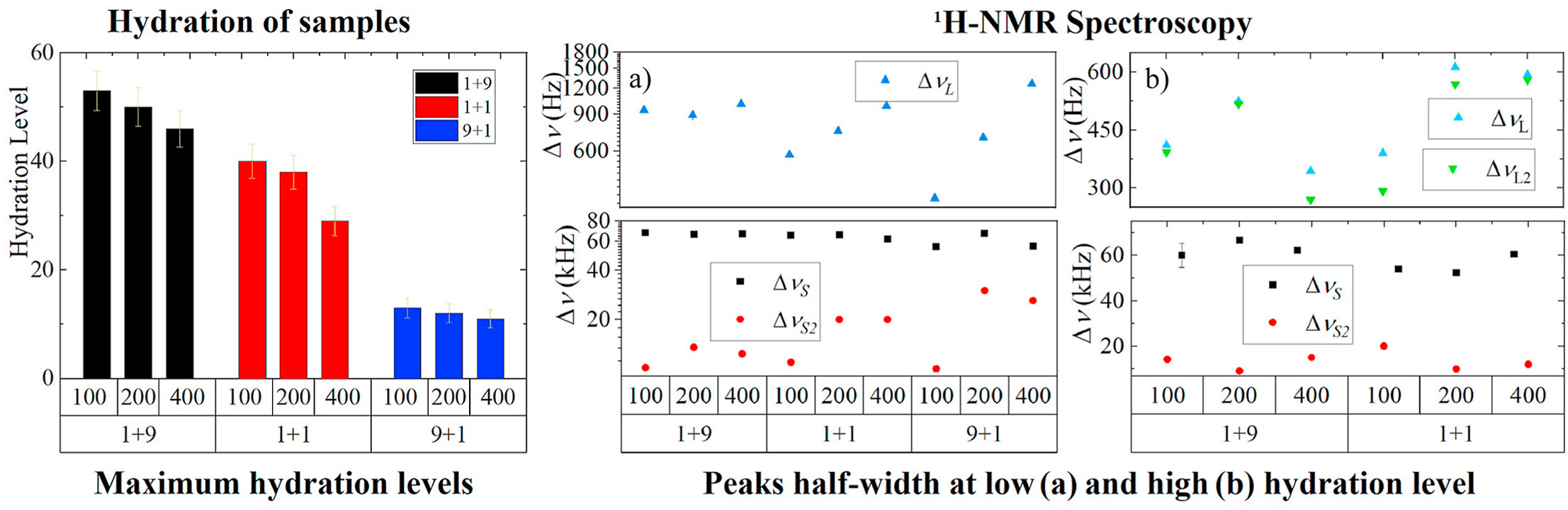

• Soluplus loading controls hydration of solid dispersions on storage.

• Rotational speed determines the space available for adsorption of water molecules.

The presence of residual water may deteriorate the performance of amorphous solid dispersions prepared by ball milling, affecting molecular mobility, crystallinity, particle size and finally, the drug dissolution rate. As the stability of these metastable systems depend on both formulation and process variables, the aim of this study was to assess for the first time, the impact that the polymer load and the rotational speed applied upon high energy ball milling could have on the performance of binary co-milled solid dispersions composed of tadalafil (a hydrophobic crystalline drug) and Soluplus (an amphiphilic, hygroscopic amorphous polymer). Each of these variables was tested at three levels. Scanning electron microscopy, laser diffraction and X-ray powder diffraction were used to analyze morphology, particle size distribution and crystallinity of ball milled formulations respectively. Dissolution studies were also carried out. Advanced tools of applied physics, namely solid state 1H NMR and relaxometry were used to assess the structure and water mobility upon gaseous phase hydration on storage. It was shown that both tested variables determined the particle size of the formulation. When the rotational speed of 400 rpm was used, all solid dispersion were XRD-amorphous, but to ensure the immediate release of tadalafil its micellar solubilization in Soluplus was necessary. While the formulation was exposed to water vapor, the hydration level increased with an increasing polymer load as well. Hence, the rotational speed governed the space available for the adsorption of water molecules and their organization in a monolayer or multilayers. Such behavior may have impact on the kinetics of the amorphous drug recrystallization, and finally deteriorate its dissolution.